(v 1.7)

Safety and usage cautions

Before installing our products, we recommend you to consult the section about safety and usage cautions at the link below.

FLUSH plates

– Elevator car column panel –

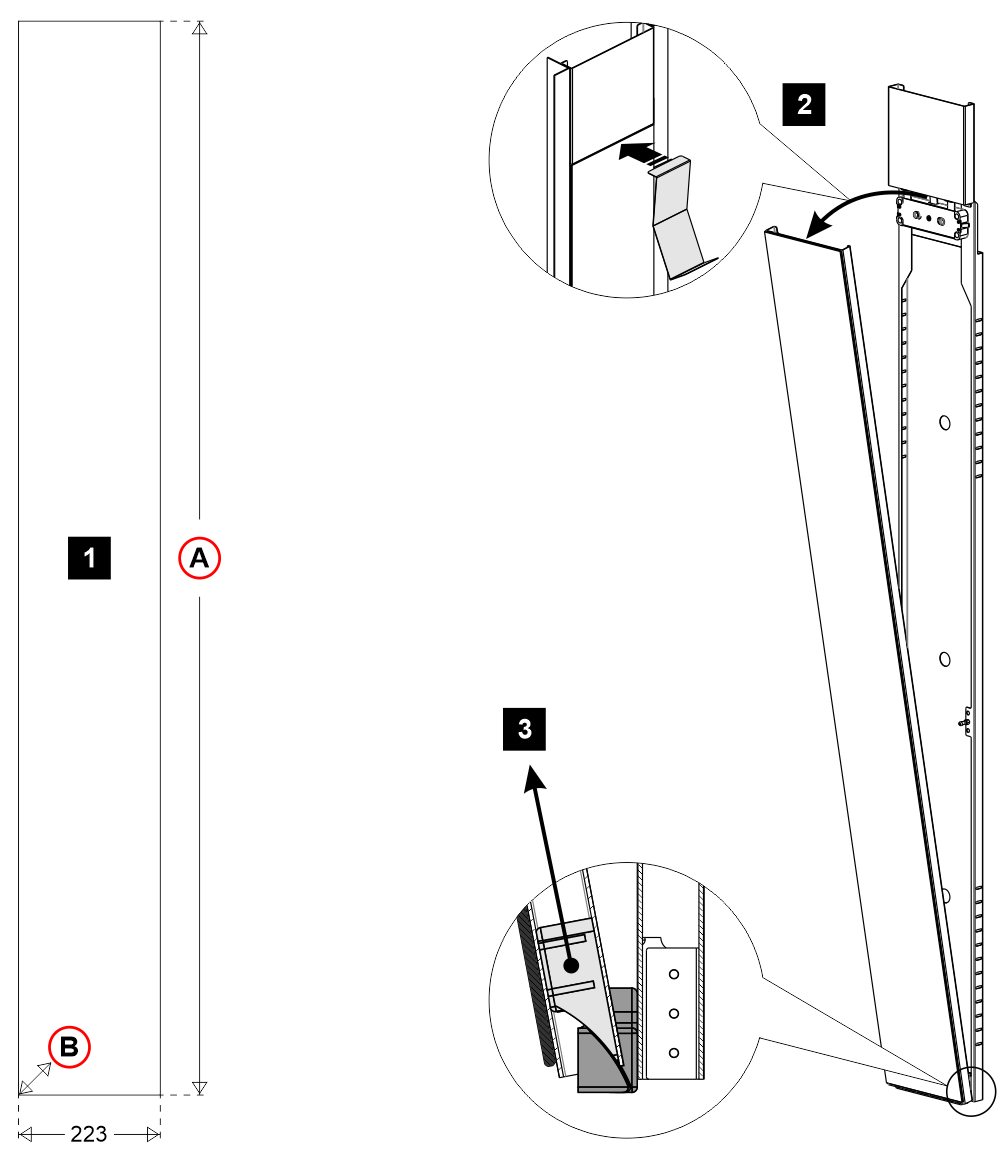

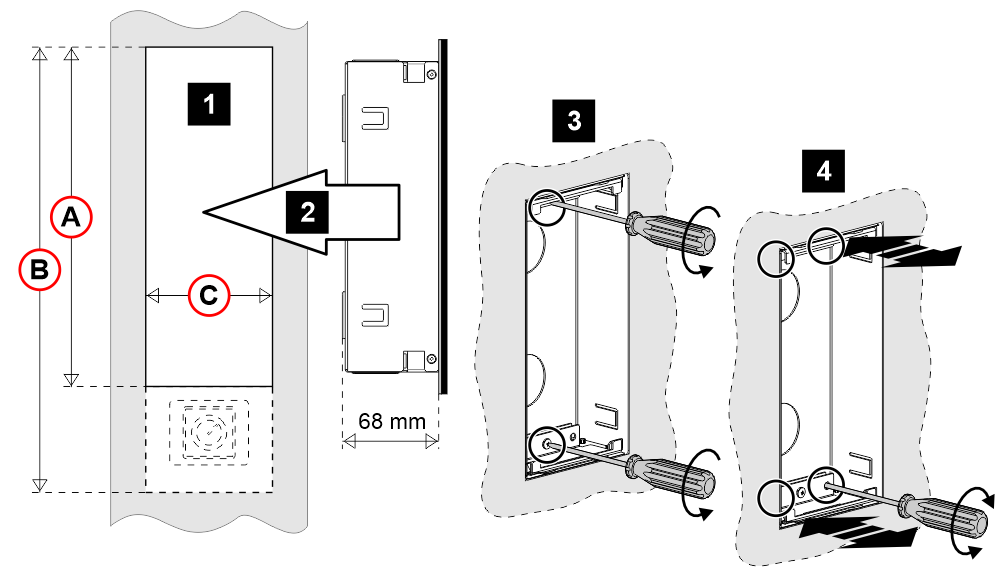

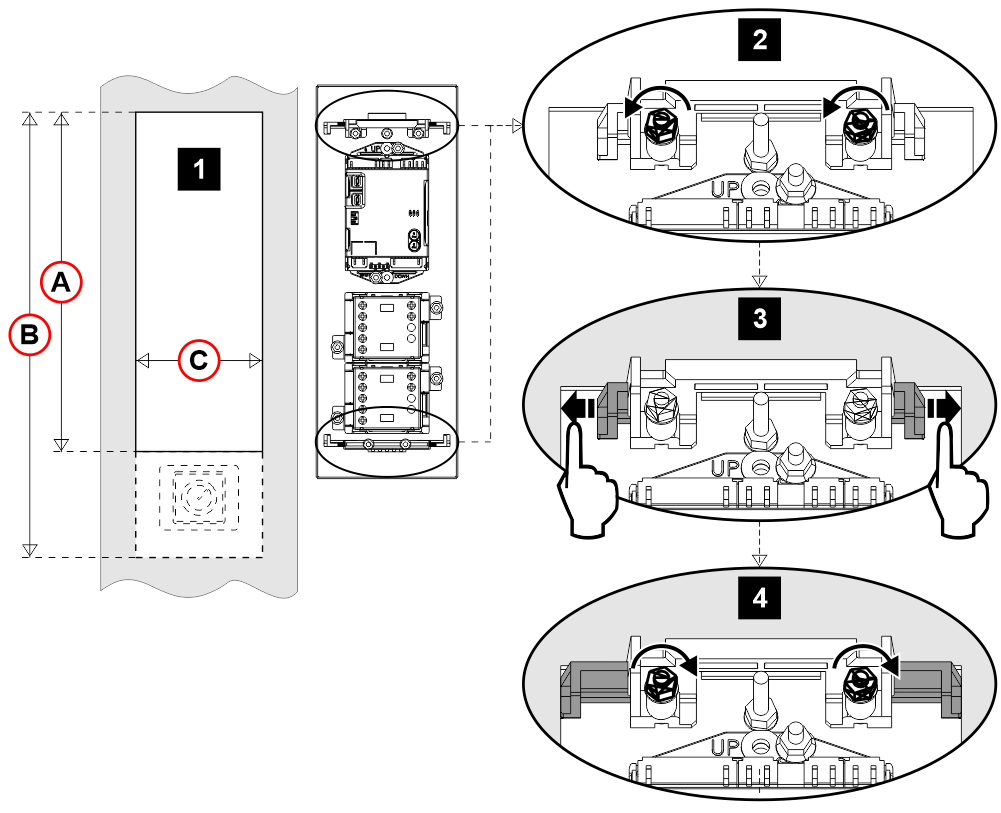

[Phase 1] – Cut-out wall of elevator car

[Phase 2/3] – Remove the column from the wall box

A) – Total heigh column + 2mm (ex. 2.115 mm + 2 mm)

A) – Total heigh column + 2mm (ex. 2.115 mm + 2 mm)

B) – Depth: 60 mm (is the minimum rear space required for the box )

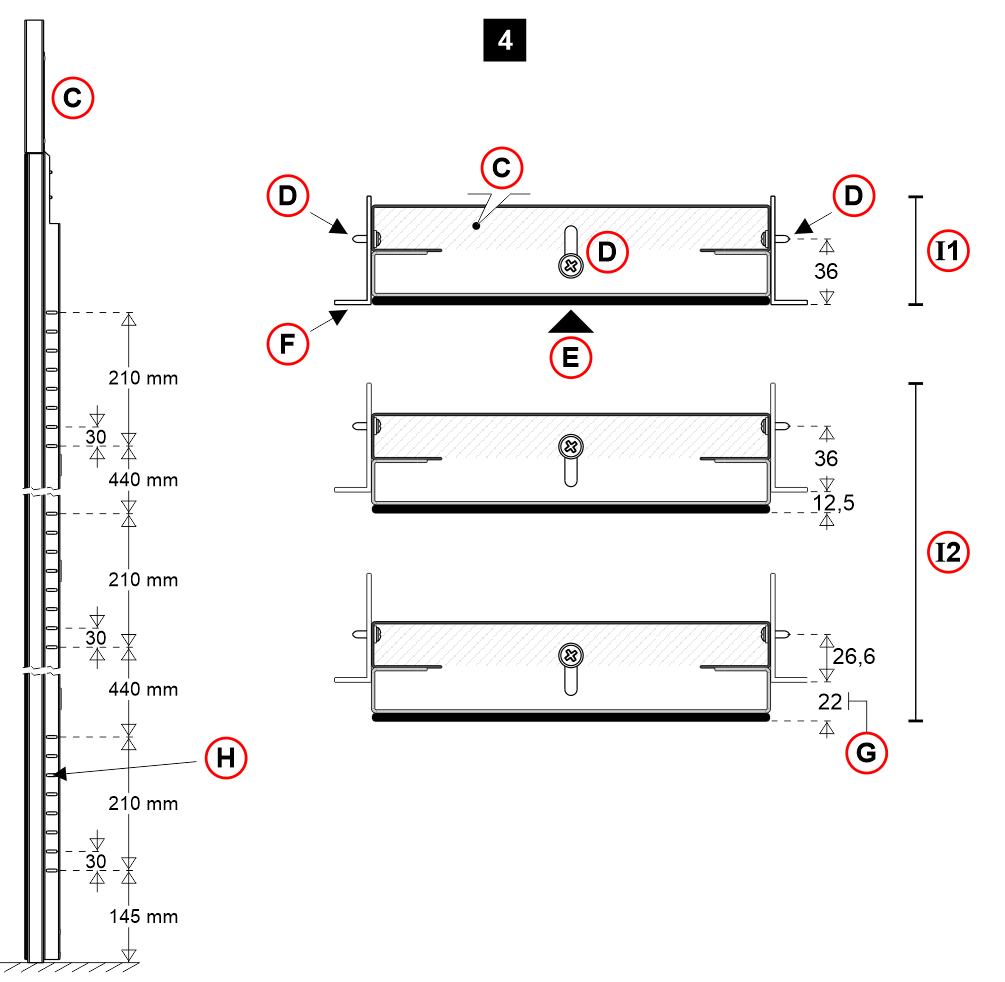

[Phase 4]– Reference settings for fixing

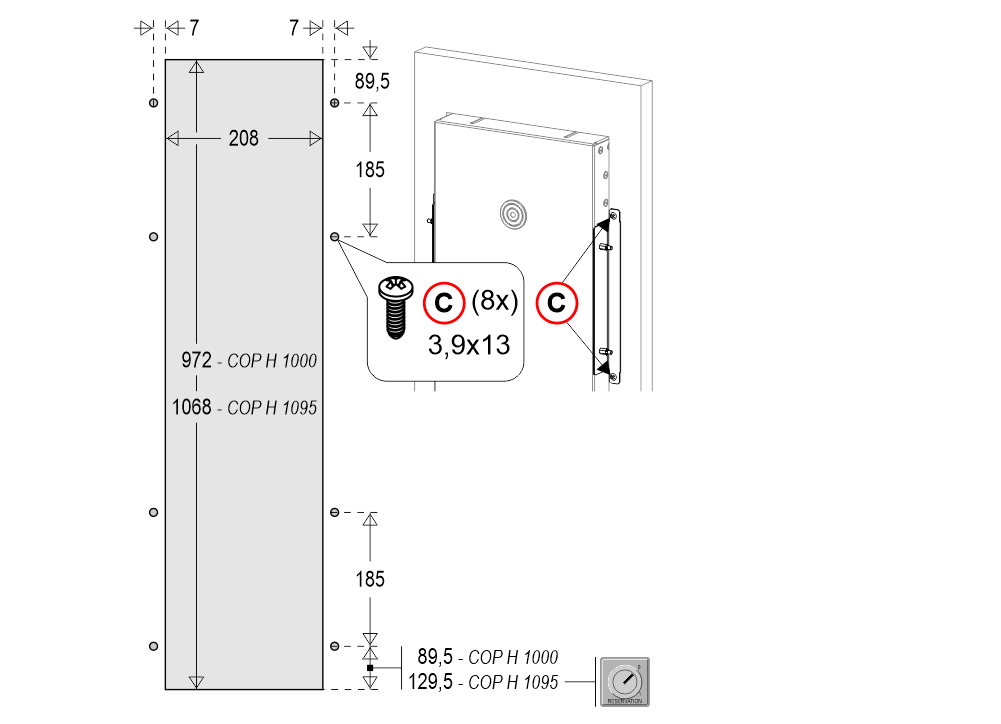

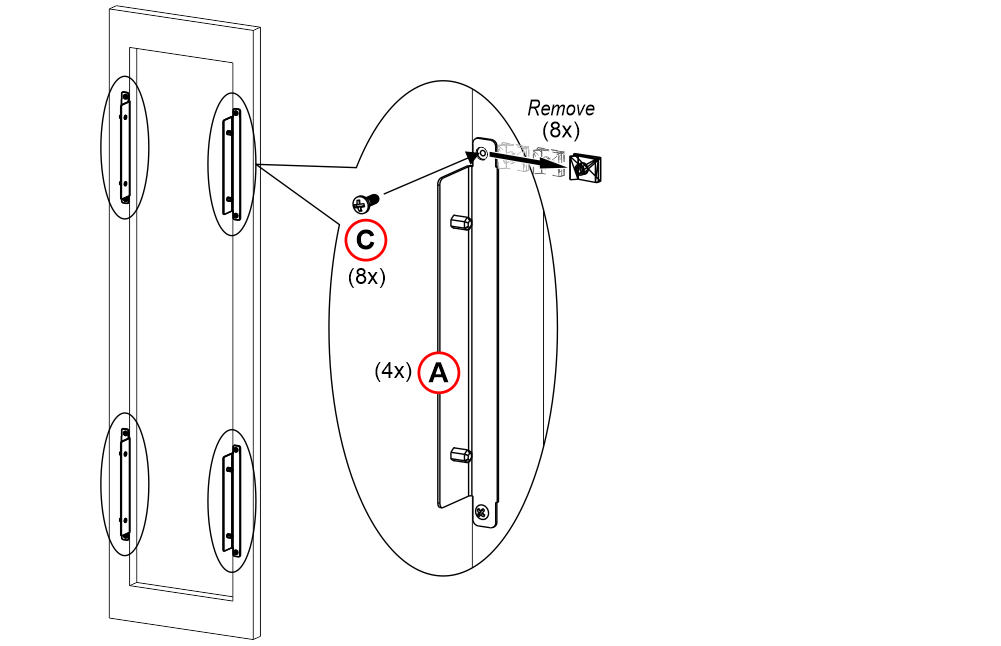

C) – Back box

C) – Back box

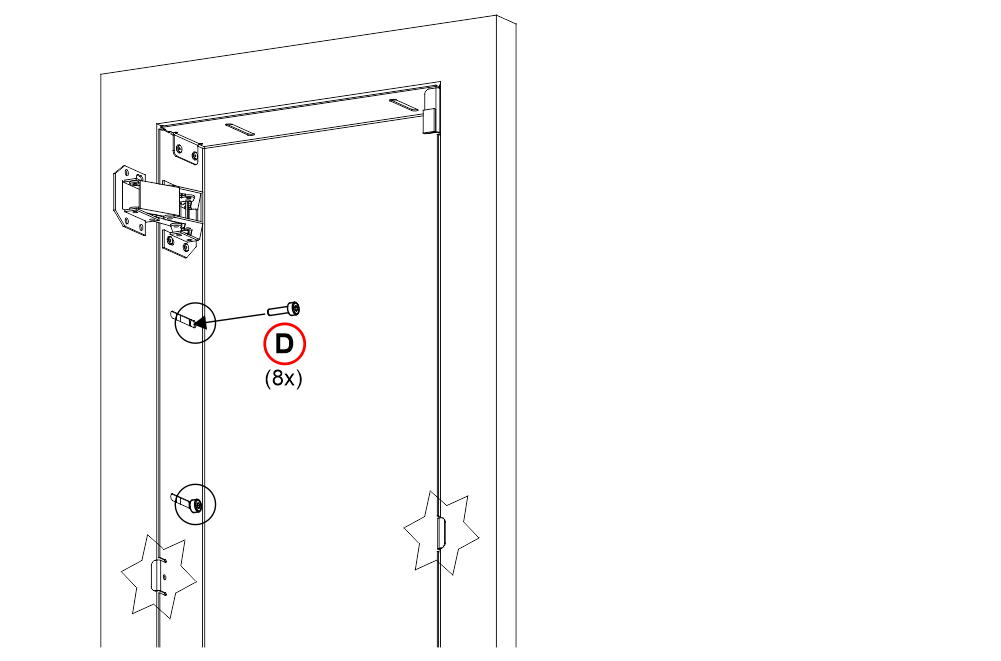

D) – Fixing screws

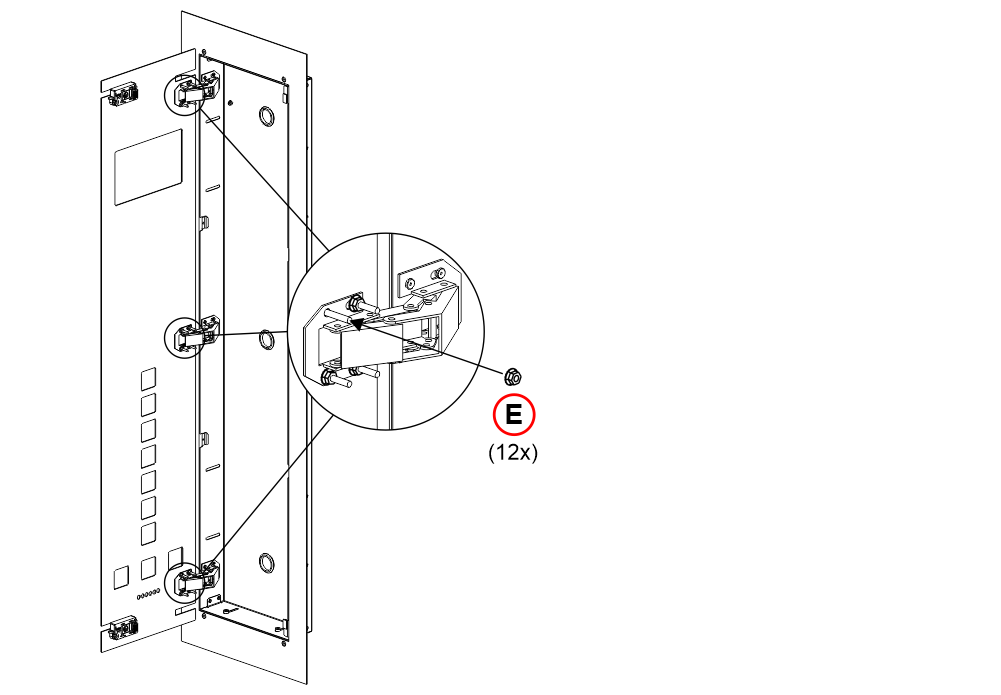

E) – Column front view

F) – Elevator car wall profile

G) – Maximum protrusion

H) – Adjustment holes

I1) – Flush plate installation

I2) – Protruding installation

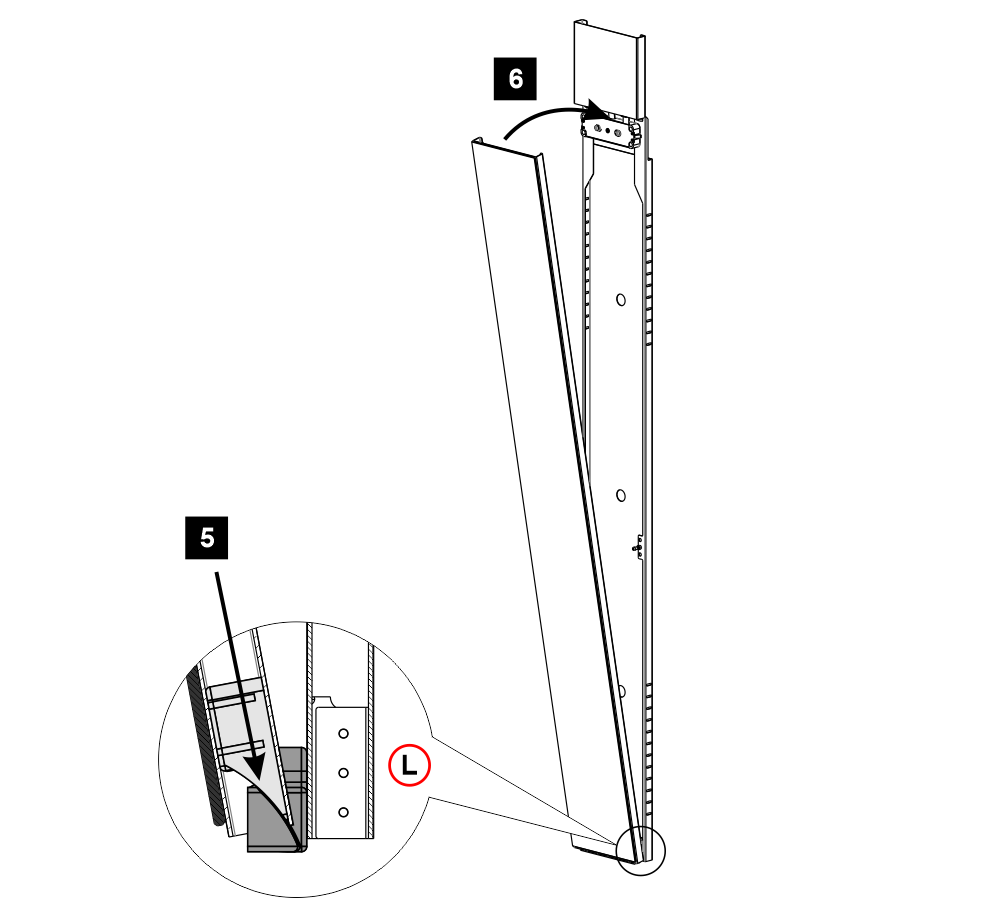

[Phase 5/6] – See below

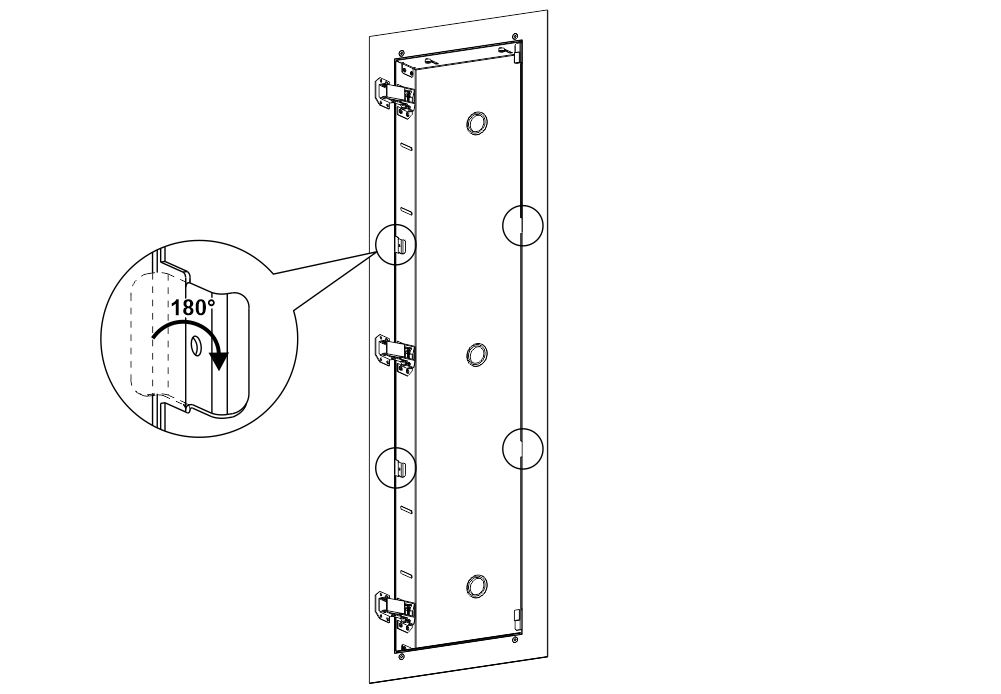

L) – Hinge detail

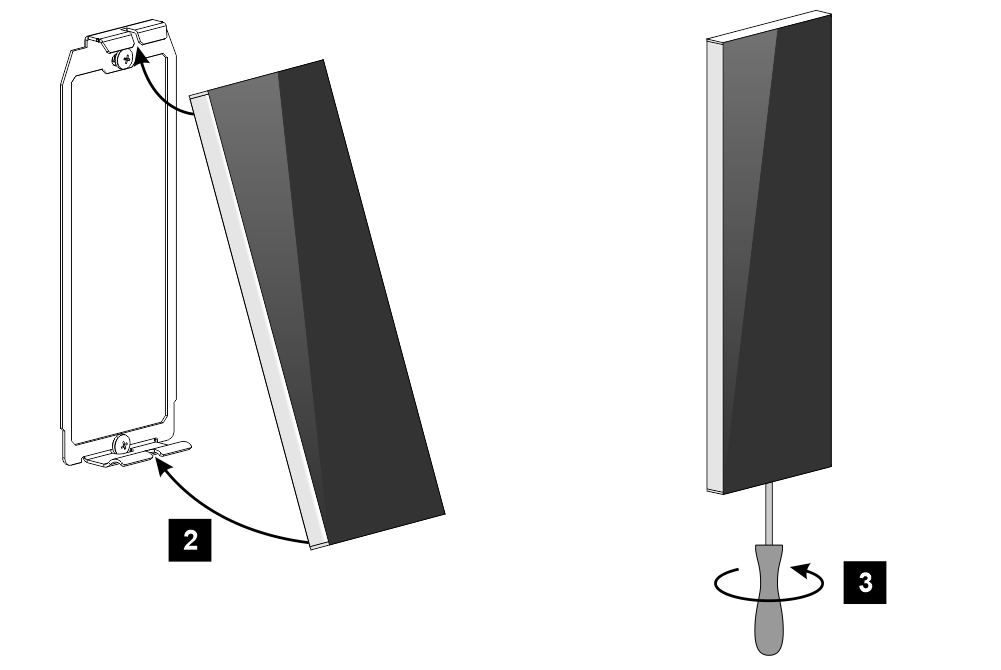

– Short elevator car panel –

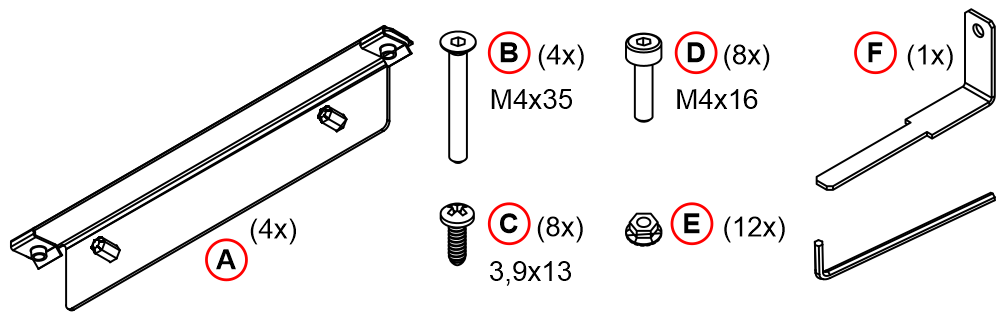

[Mounting kit]

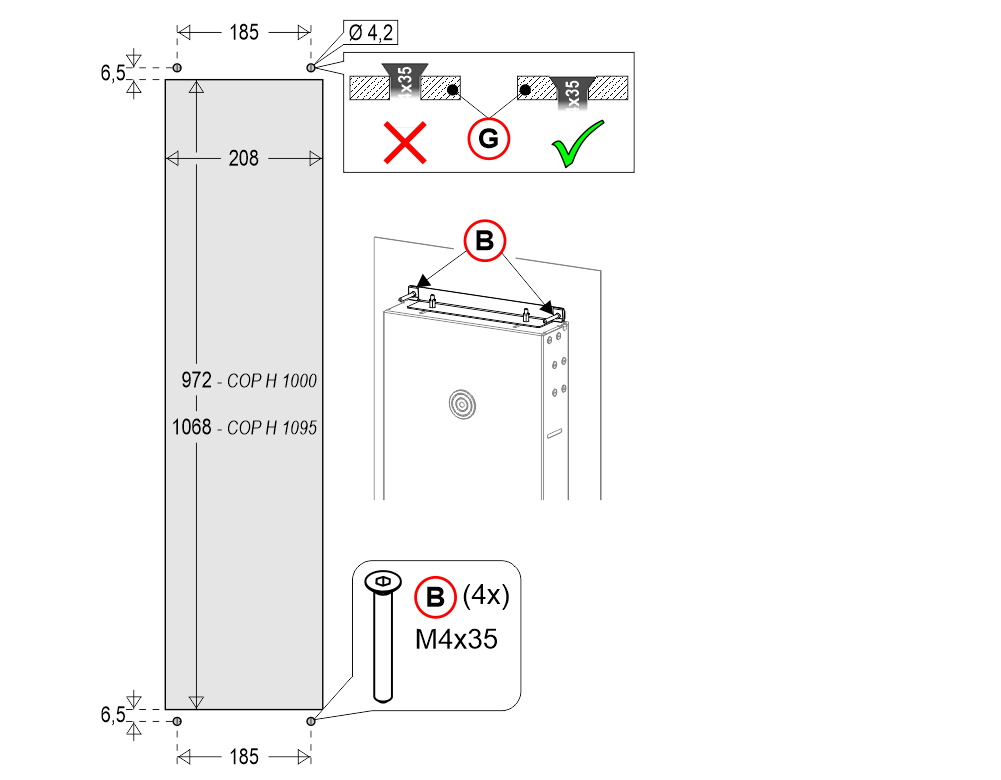

[Cut-out] – FRONT fixing

G) – Elevator car wall

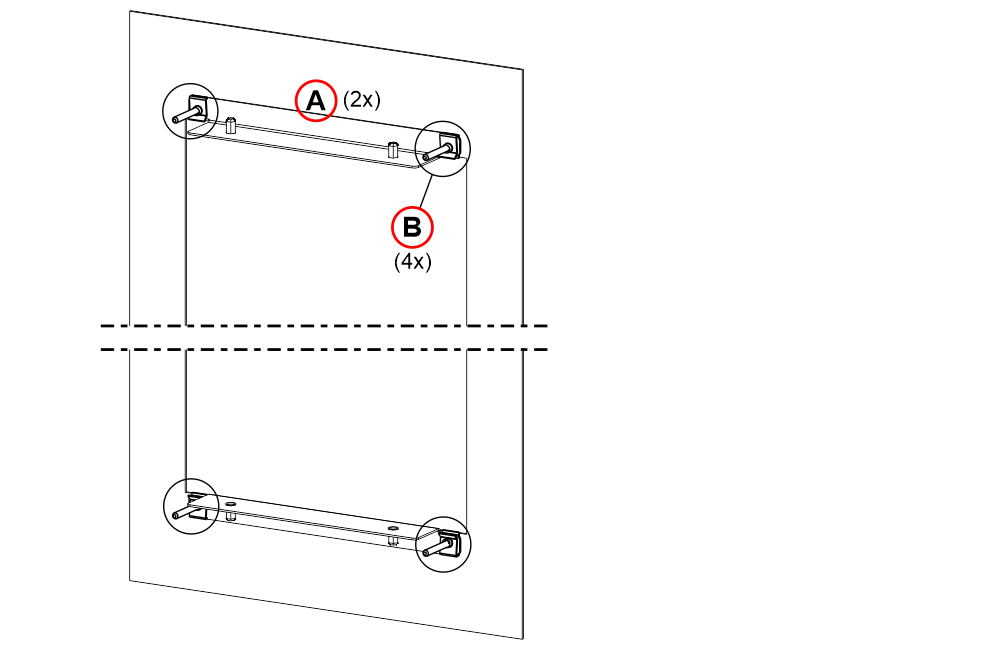

[Phase 1] – See below (back view)

[Phase 2] – See below (front view)

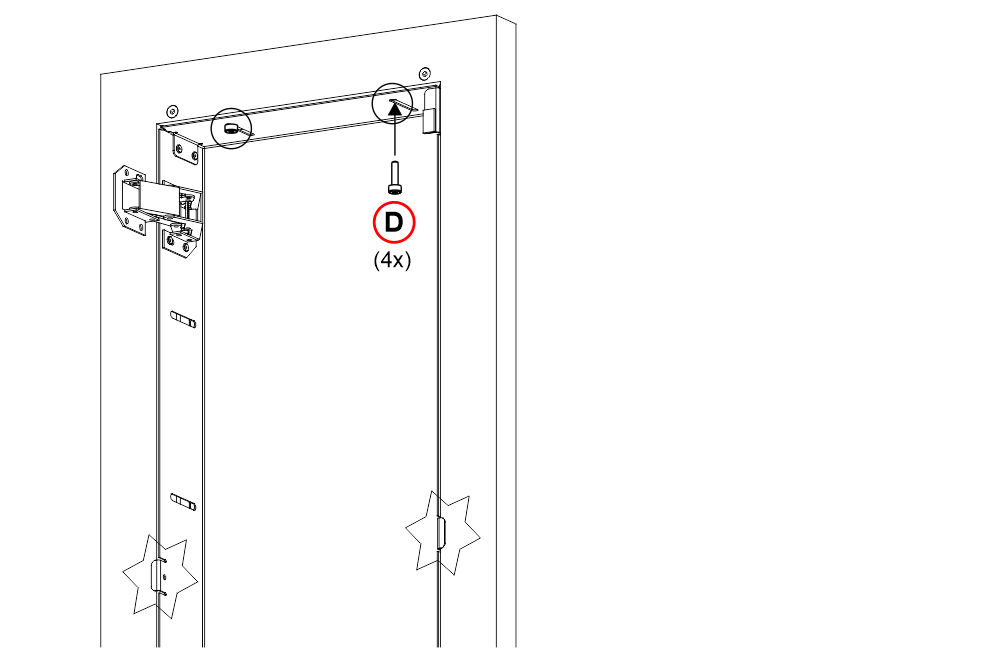

Insert the box up to the flap and fasten it (D)

Insert the box up to the flap and fasten it (D)[Cut-out] – BACK fixing

The 8 holes must NOT be made on the front view of the elevator car wall.

The 8 holes must NOT be made on the front view of the elevator car wall.[phase 1] – See below (back view)

[Phase 2] – See below (front view)

Insert the box up to the flap and fasten it (D)

Insert the box up to the flap and fasten it (D)[Phase 3] – Fold the flaps (See below)

[Phase 4] – See below

[Phase 5] – See below

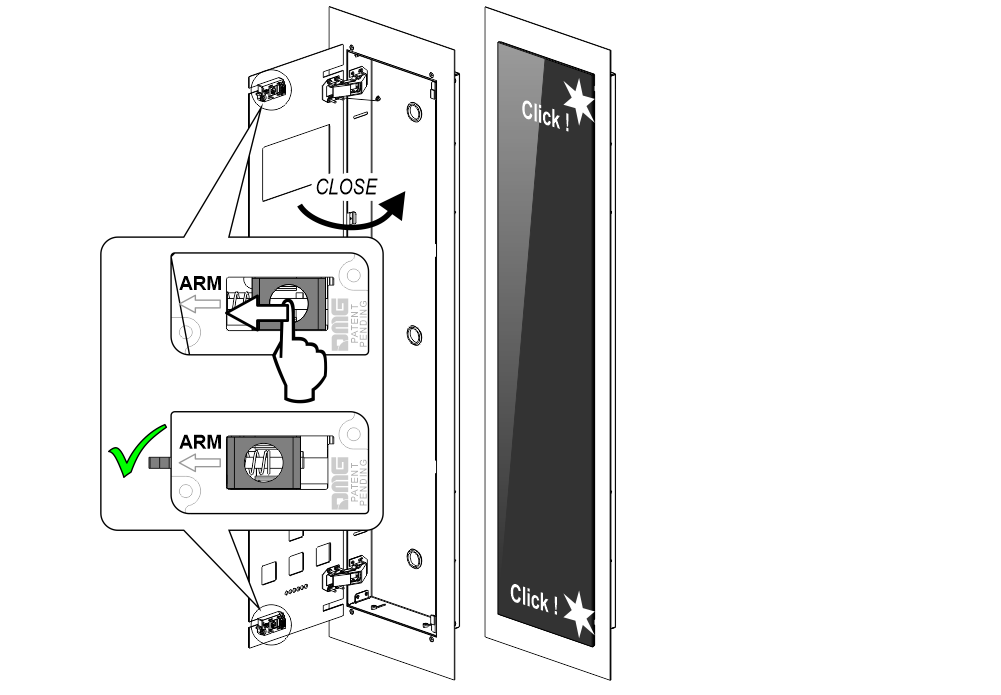

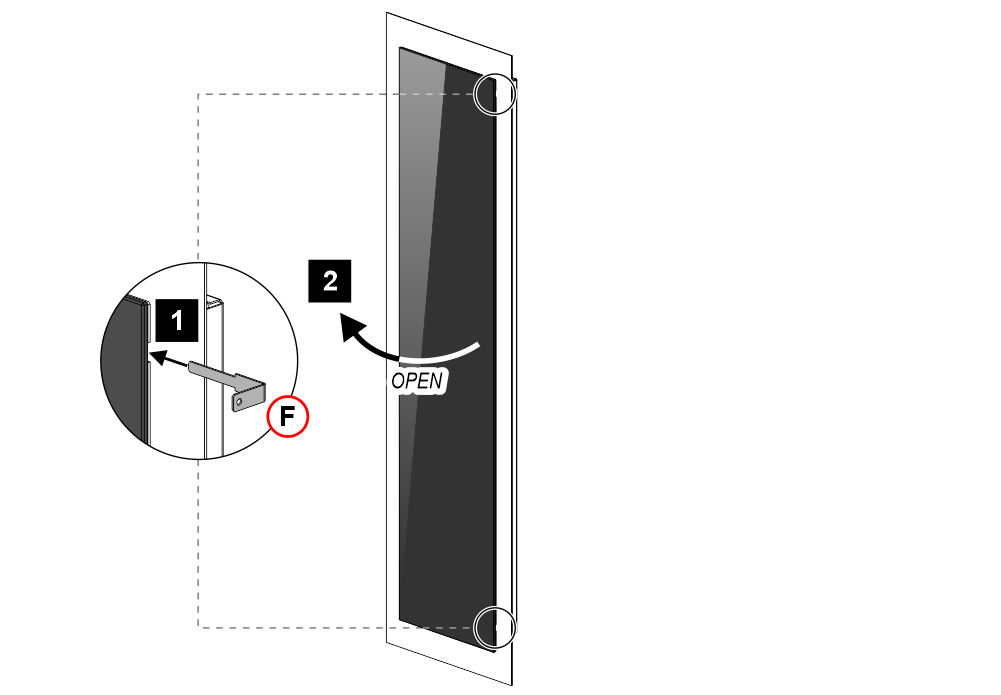

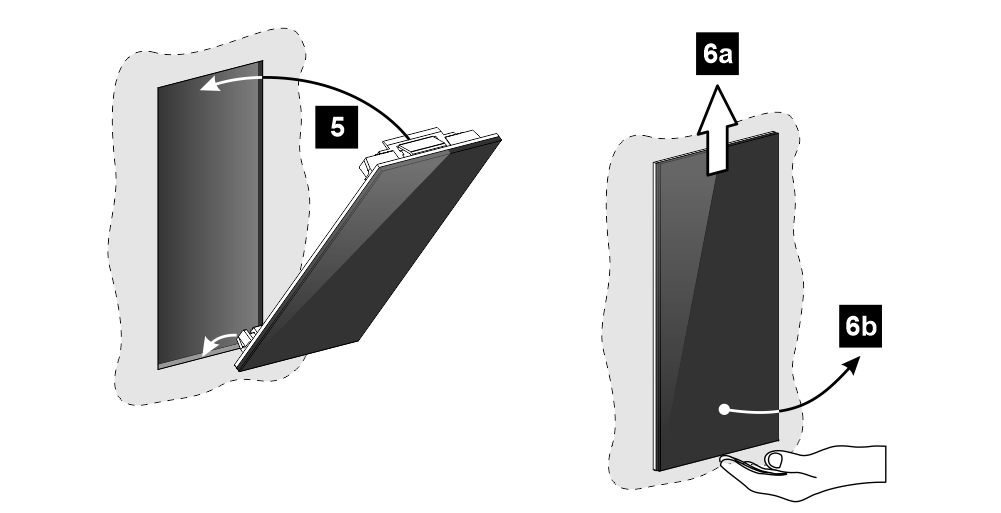

[Open the elevator car panel] – See below

– Floor panel –

(with back box)

[Phase 2] – Insert the back box.

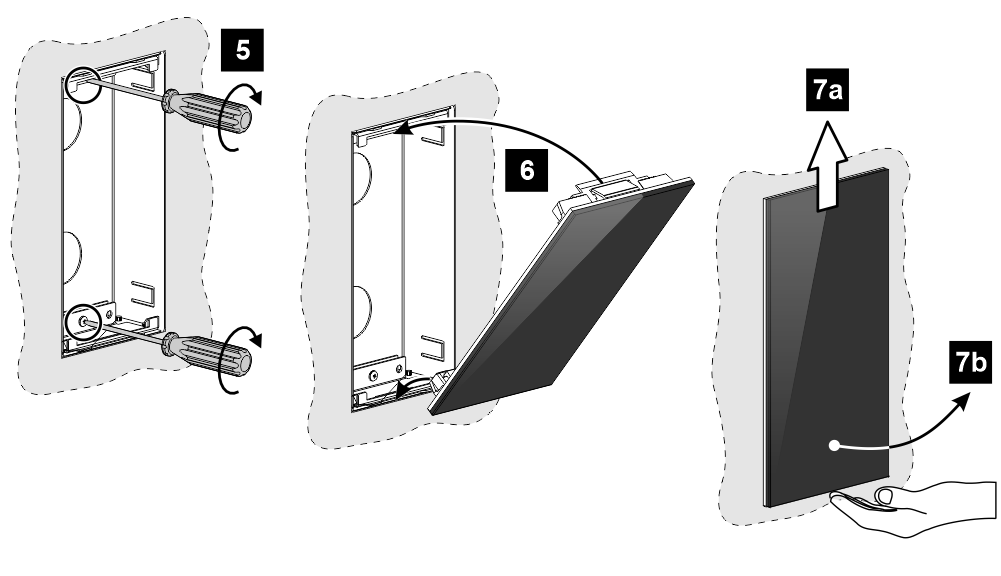

[Phase 3] – Loosen the two central screws.

[Phase 4] – Adjust the depth of the two brackets.

A) – 222 mm (LOP h250 mm without key)

B) – 299 mm (LOP h320 mm with key)

C) – 82,5 mm (LOP 90 mm) / 124 mm (LOP duplex 130 mm) / 85 mm (LIP 90 mm horizontal)

[Phase 5] – Tighten the two central screws.

[Phase 6] – Close the floor panel.

[Phase 7] – Dismantling the floor panel.

[Phase 2] – Loosen the 4 nuts.

[Phase 3]

[Phase 4] – Tighten the 4 nuts.

A) – 211,5 mm (LOP h250 mm without key)

B) – 288,5 mm (LOP h320 mm with key)

C) – 80,5 mm (LOP 90 mm) / 124 mm (LOP duplex 130 mm) / 82,5 mm (LIP 90 mm horizontal)

[Phase 5] – Close the floor panel.

[Phase 6] – Dismantling the floor panel.

SURFACE plates

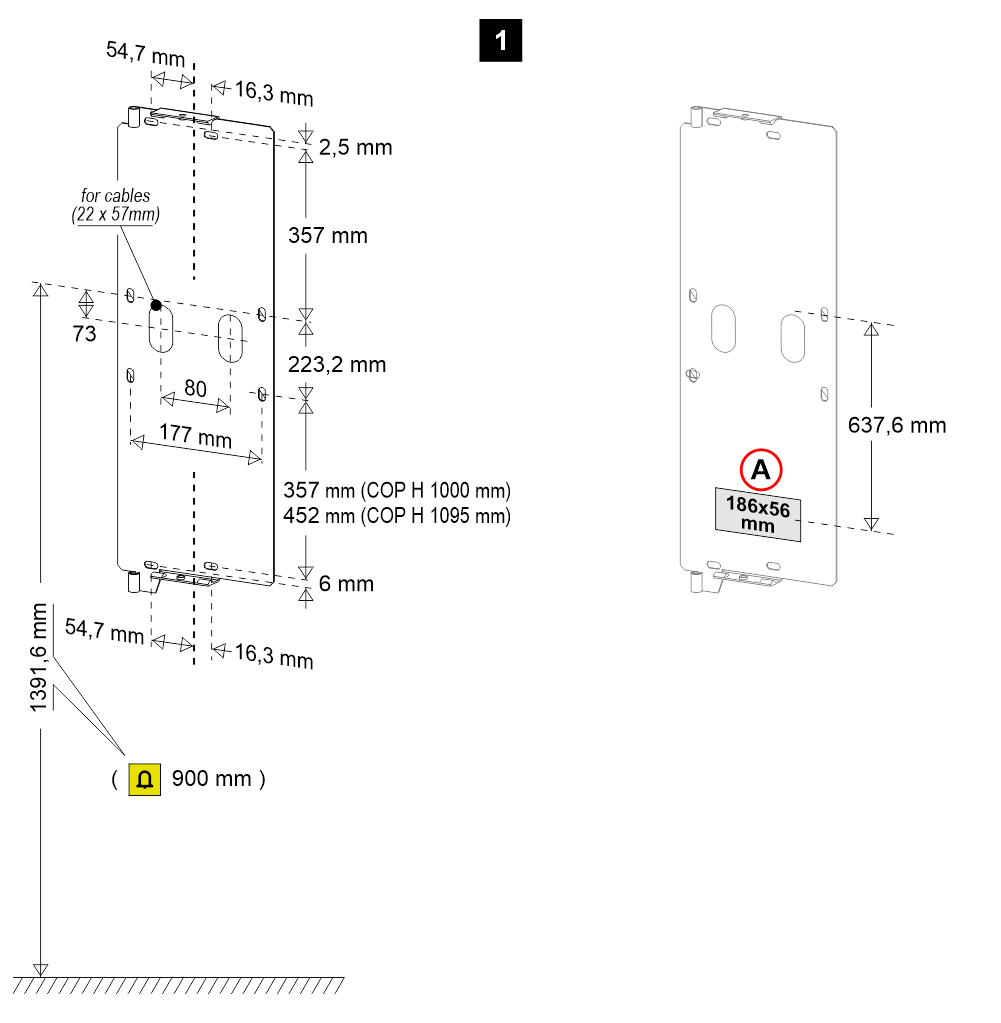

– Elevator car column panel –

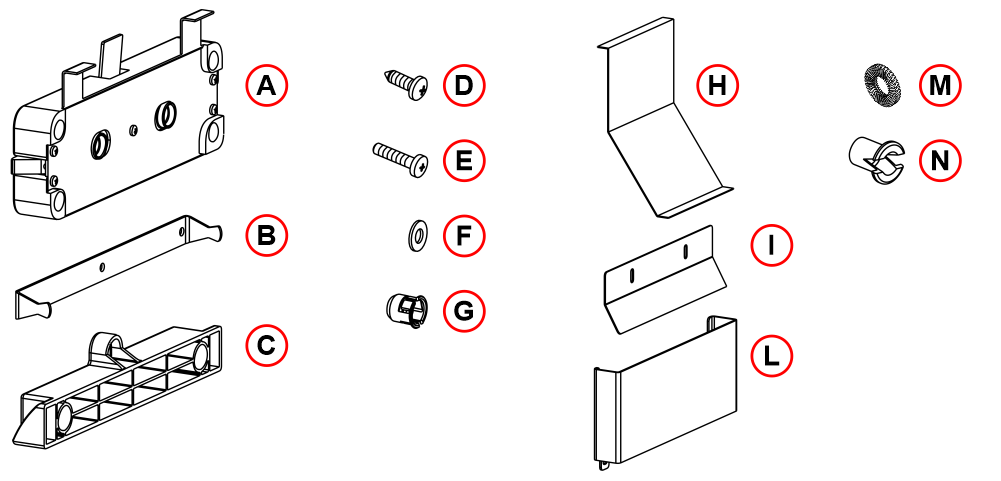

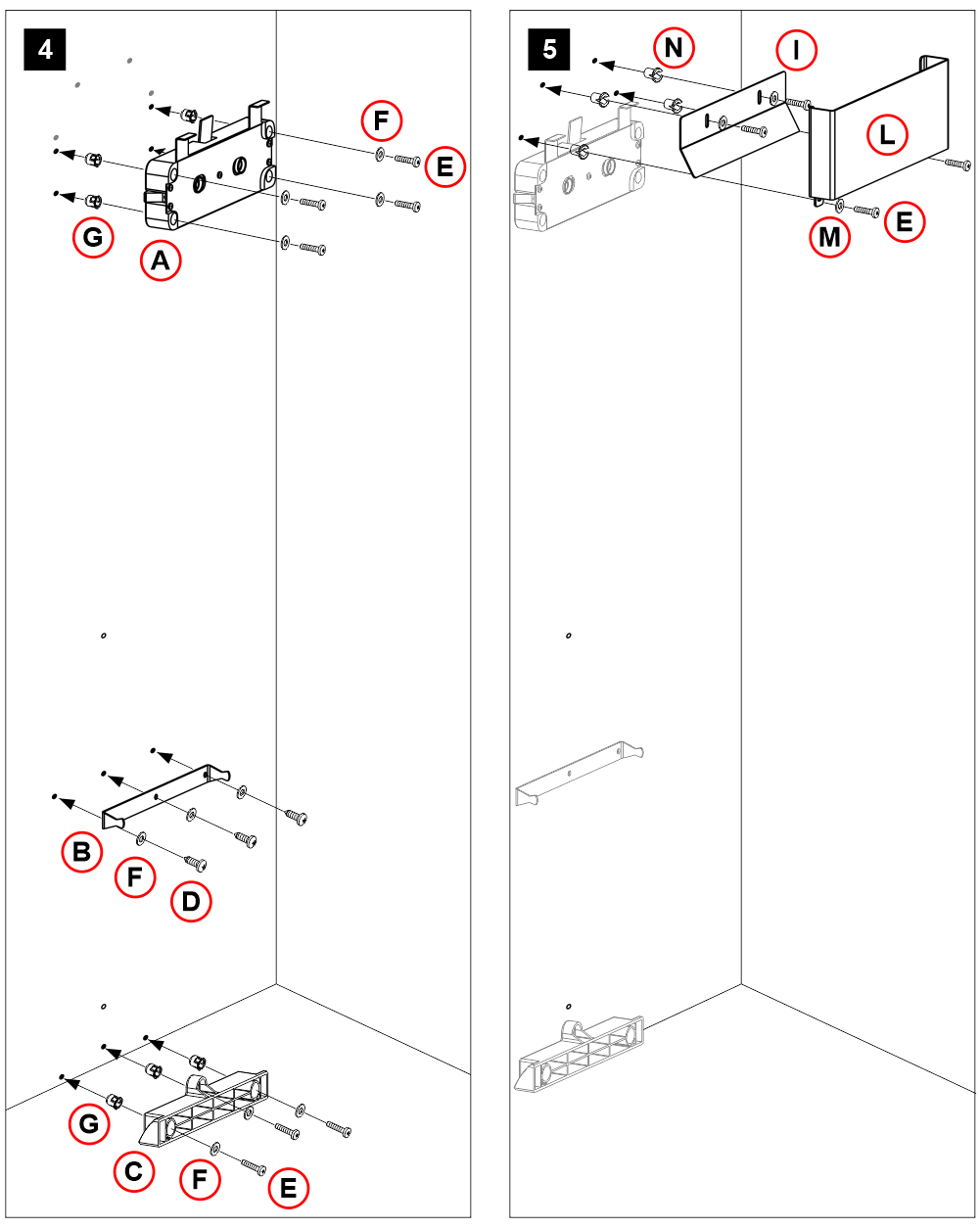

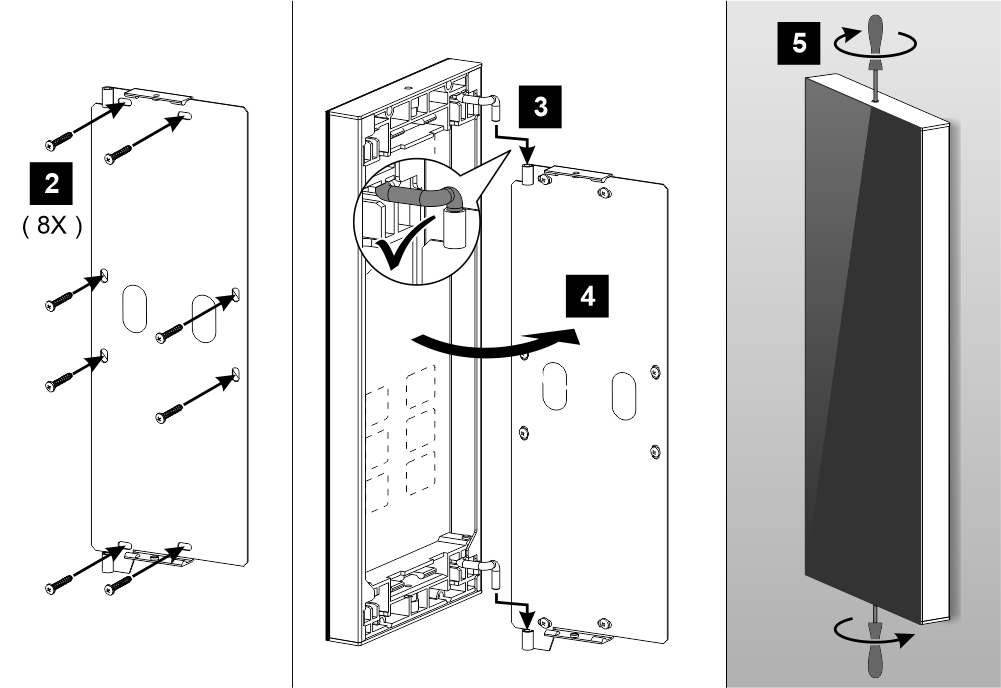

[Mounting kit]

A) – 1 Lock B) – 1 Central stirrup C) – 1 Hinge D) – 6 Self tapping screw 3,9 x 13

E) – 11 Screw M4 x 18 F) – 10 Flat washer G) – 7 Round cage nut H) – 1 Opening tool

I) – 1 Ceiling support L) – 1 Ceiling adapter M) – 4 Crinkle washer

N) – 4 Threated Polyammide bush M4

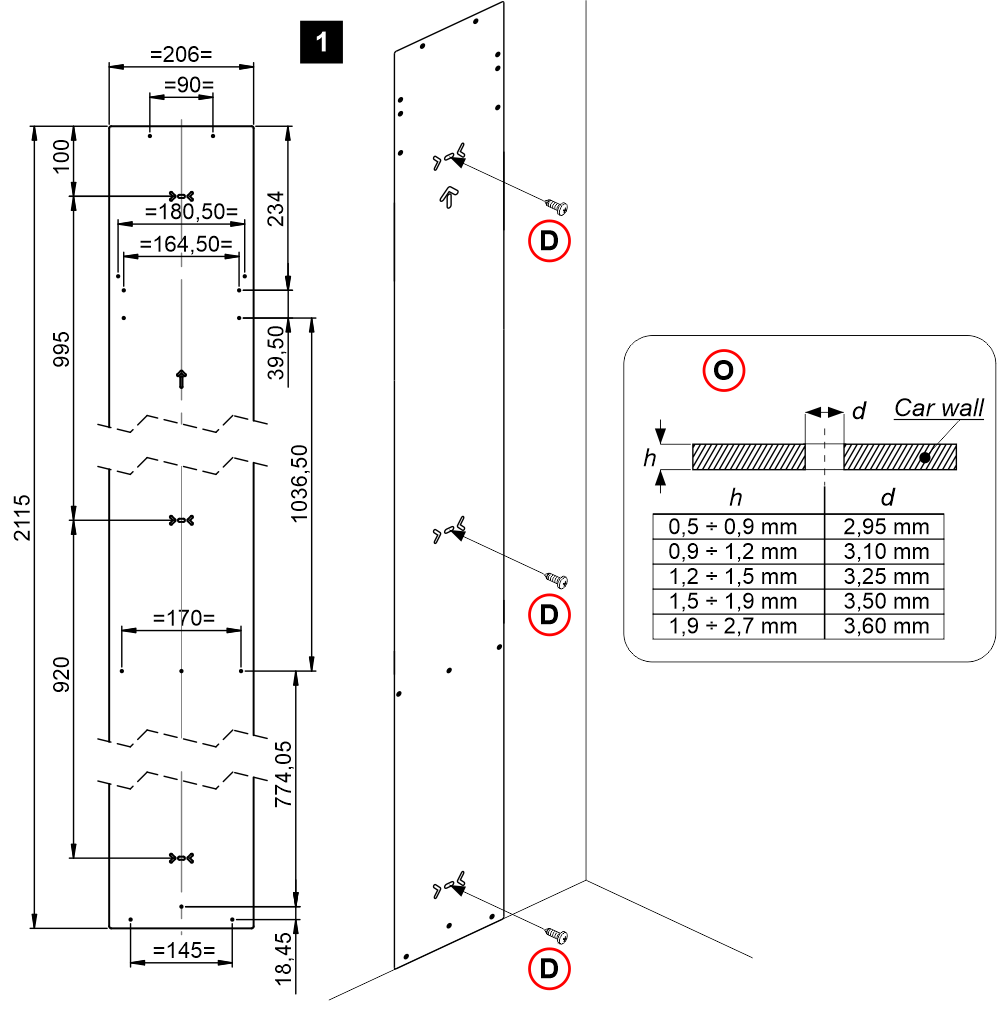

[Phase 1] – Approach the jig to the wall, drill the 3 holes and fix the jig with the screws (D). The central fixing is optional.

O) – Self tapping screw hole table (Ø 3,9 mm)

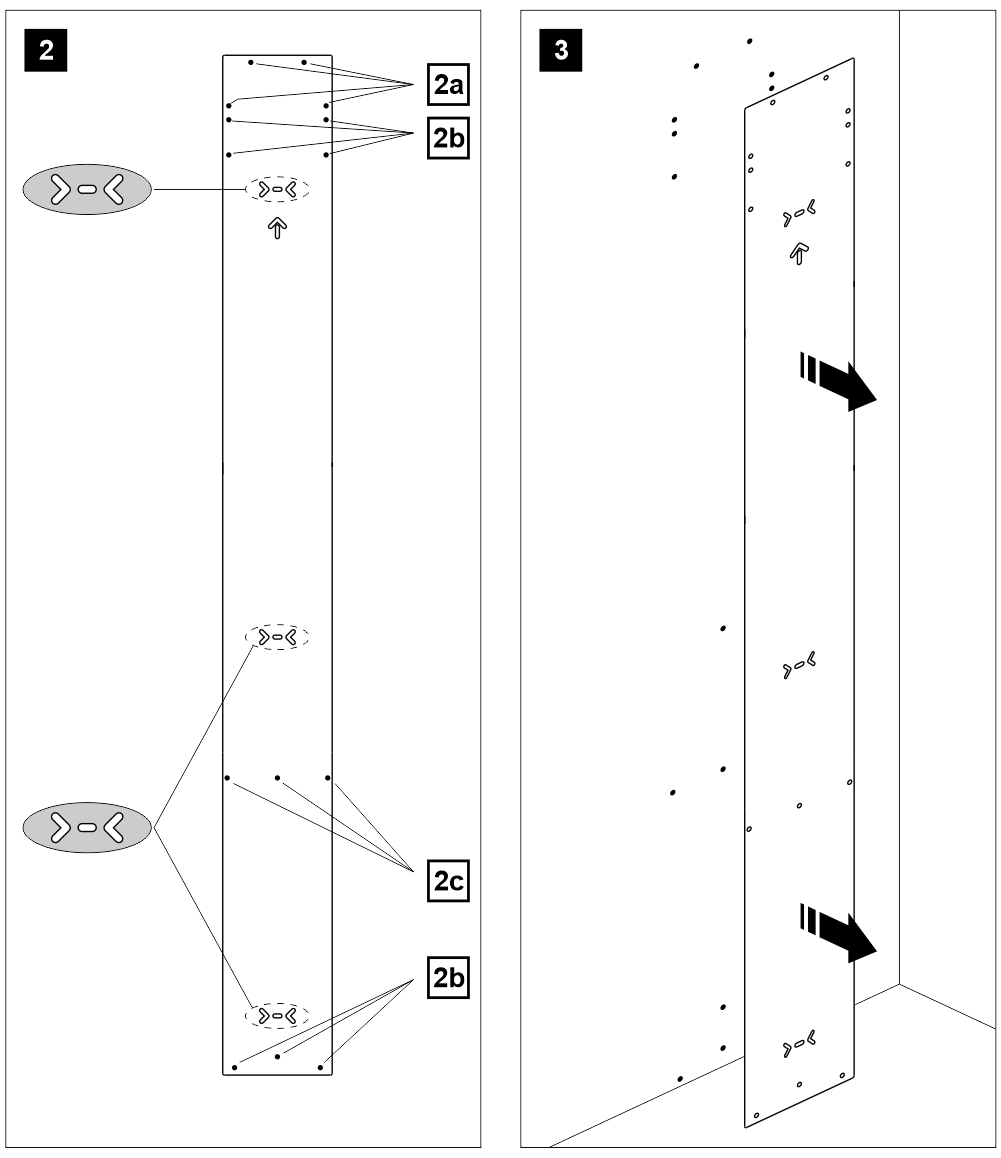

[Phase 2] – Drill according to indications

[Phase 3] – Remove jig.

[2a] – Ø 6 mm

[2b] – Ø 10 mm

[2c] – Central stirrup (see “Self tapping screw hole table“)

[Phase 4/5] – See below

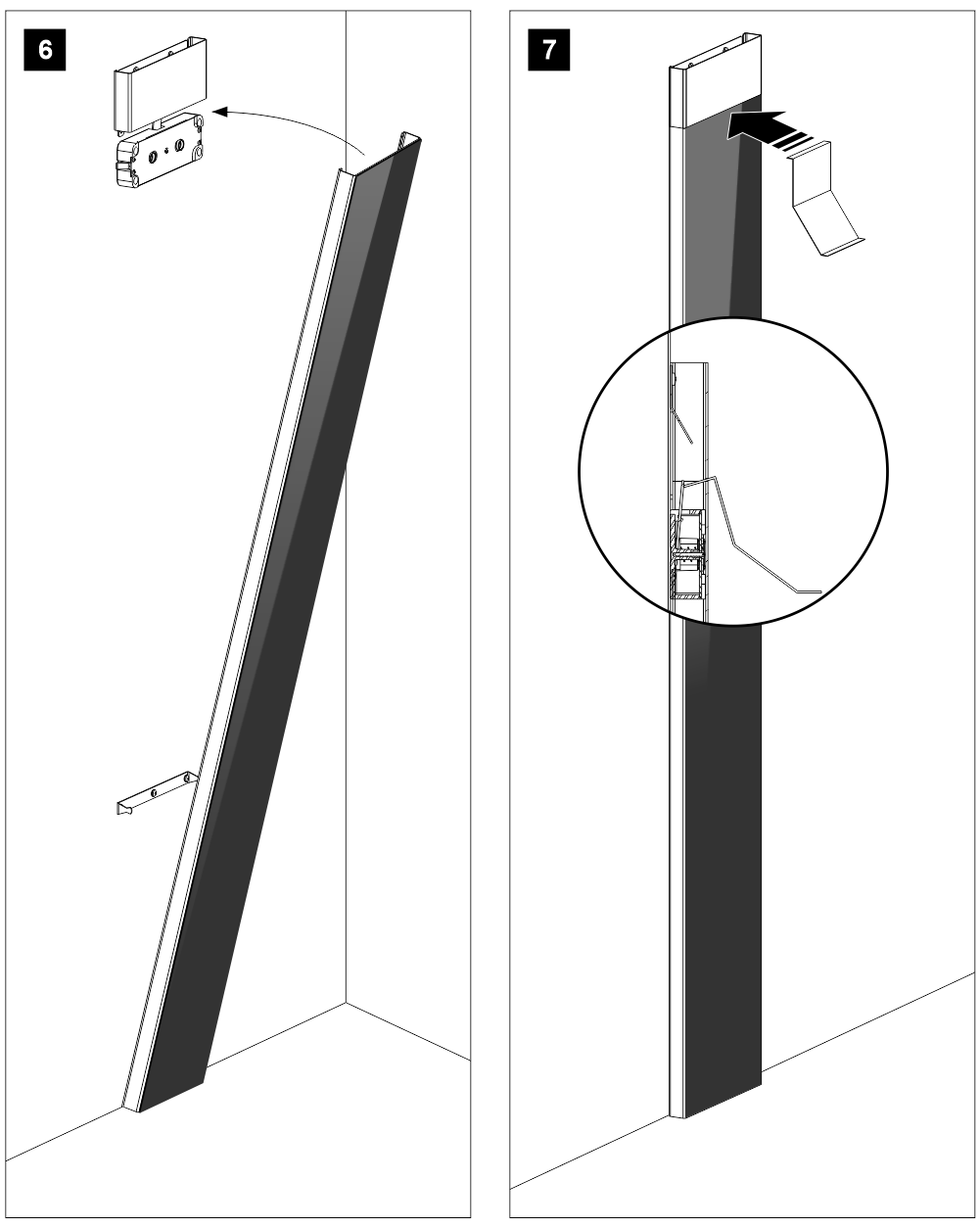

[Phase 6] – Insert the column into the hinge and hook to the lock.

[Phase 7] – Push the opening tool (H) to unlock and pull it to open the column.

– Short elevator car panel –

[Phase 1] – See below

A) – Cut-out elevator car wall required for plates 1095mm high (with service keys)

[Phase 2÷5] – See below

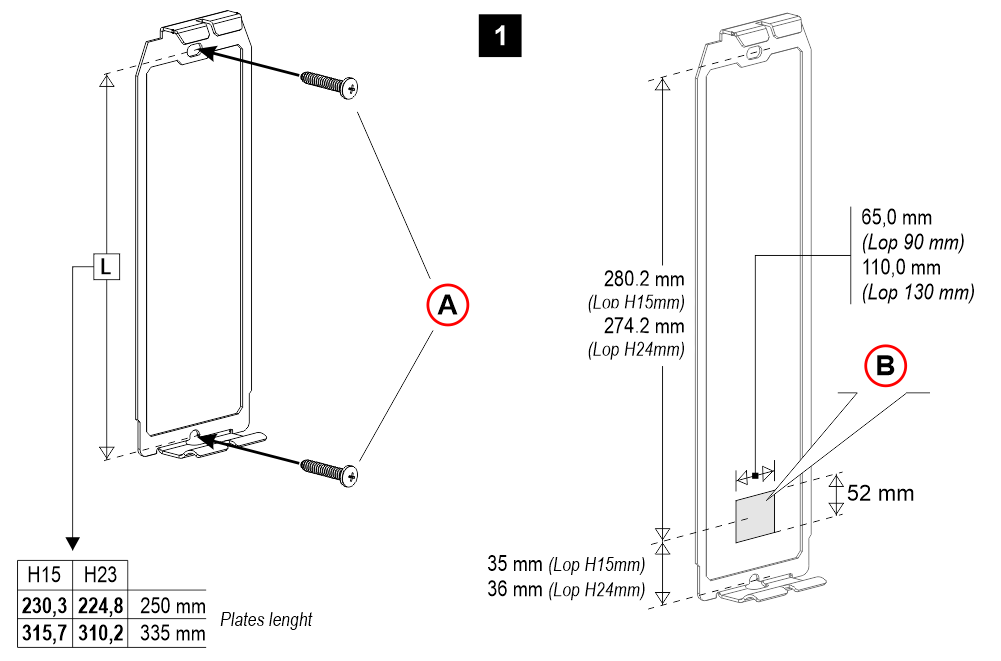

– Floor panel –

[Phase 1] – See below

A) – 2 screws: 90 mm width plates / 130 mm width plates H23

4 screws: 130 mm width plates H15

B) – Cut-out wall required for 335mm lenght plates (with key)

[Phase 2/3] – See below

Touch push button

Touchless push button

Download

| Reference | Version | Link |

|---|---|---|

| 1.6 | Download PDF (English) | |

| Fixed error | 1.7 (current version) | Download PDF (English) |