(v 1.0)

Safety Cautions

Power Requirements

Be sure to use only an adapted power. The use of a power different than the specified type may damage the unit and pose a safety hazard. Connect the power only to an outlet that supplies the rated voltage required by the product. You should always turn off the power before connecting or disconnecting any cables.

Battery Operation

Pay close attention to the labelling of the battery to make sure you choose the correct type. When not using the unit for an extended period, remove the batteries from the unit. If battery leakage has occurred, wipe the batery compartment and the battery terminals carefully to remove all remnants of the battery fluid.

Environment

To prevent the risk of fire, electric shock or malfunction, avoid installing your product in environments where it will be exposed to: Extreme temperatures, heat sources or naked flame, high humidity or moisture, excessive dust or sand, excessive vibration or shock.

Handling

Never place objects filled with liquids, such as vases, on the product since this can cause electric shock. Do not place naked flame sources, on the produtc since this can cause fire. Do not exert undue pressure on the keys and other controls. Also take care not to drop the unit, and do not subject it to shock or excessive pressure. Take care that no foreign objects or liquids can enter the unit.

Alterations

Never open or attempt to modify the product in any way since this can result in damage to the unit.

Electrical Interference

All electronic devices mounted in the elevators are subject to electrical noises generated by power equipment incorporated in the elevator system. Great care was taken during design and production of our electronic devices in order to protect inputs and outputs in such a way as to render them as far as possible, insensitive to noises. Apart from this, to be able to guarantee the correct functioning of our devices we would like to give you some more suggestions.We briefly describe what precaution to use according to the power equipment.It is always a good practice to connect the protection described below as near as possible to the source of noises.

Protections

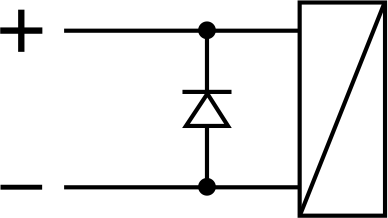

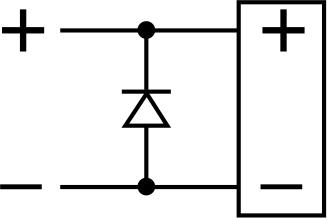

D.C. power relays

Connect in parallel to coil of power relay one diode BY255 (3A- 1300V) as near to coil as possible.

Coil of Power Relay

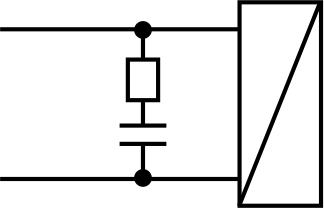

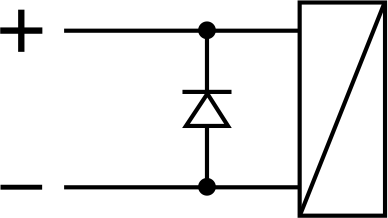

A.C. power relays

Connect in parallel the coil of power relay one resistor of 4.7 ohm 1W and one capacitor of 0.22 μF 400V, as near to the coil as possible.

Coil of Power Relay

Note: It is sometimes necessary to use the same type of protection as described under 1 and 2 above for some relays on the control board. It is not possible to define which and how many relays should be protected on the control board but it is a good practice to provide the protection of all power relays on control board during the construction.

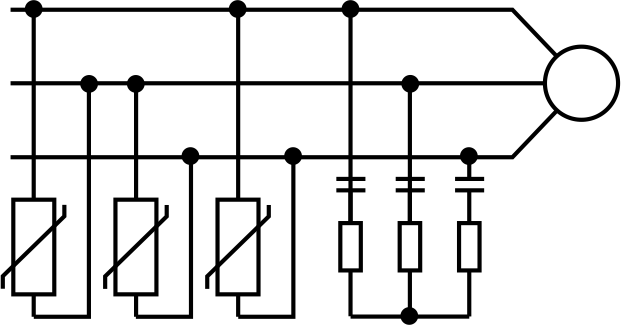

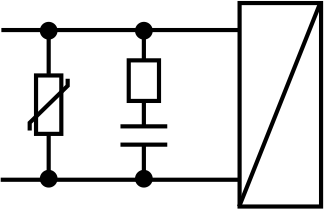

Lift Motor

Connect in parallel to the motor phases (high speed) varistors of 460V and capacitors of 0.68 μF 630V in series to resistors of 4.7 ohm 3W as near to motor as possible. The same operation has to be repeated for low speed motor connections.

Varistors – Lift Motor

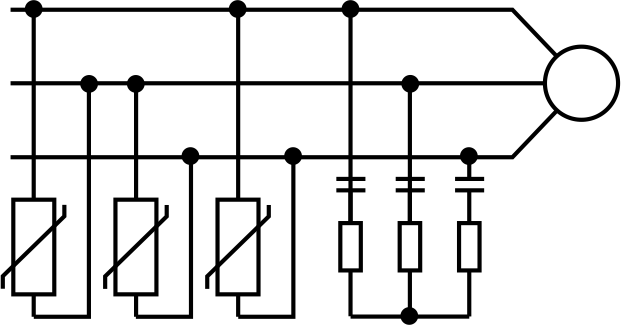

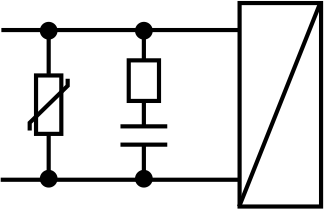

A.C. motor of door operator

Connect in parallel to the motor phases varistors of 460 Volt and capacitors of 0.68 μF 630V in series to resistor of 4.7 ohm 3W as near to the motor as possible.

Varistors – Operator Motor

Motor with brake circuit with DC injection

Connect in parallel to the motor brake circuit one diode BY255 as near to the motor as possible.

Brake Circuit

D.C. Cams

Connect in parallel to the coil of cams one diode BY255 as near to the coil as possible.

Coil of Cams

A.C. Cams

Connect in parallel to the coil of cams one varistor of 250V, one resistor of 4.7 ohm 3W, one capacitor of 0.68 μF 630V as near to the coil of the cams as possible.

Coil of Cams

Cabin Illumination

Connect in parallel to the main supply of the car lamp one varistor of 250V, one resistor of 220 ohm 1W and one capacitor of 0.33 μf 400V as near as possible to the car lamp (on the main supply on the car roof).

Neon Lamp

Cleaning Instructions

Many DMG products are made of polycarbonate parts, currently featuring Bayer’s Makrolon type 2407, 2805 and 2807. Products currently featuring this type of material are: pushbuttons, indicators, positon indicators and other plastic components.

To ensure proper cleaning of its products and to avoid damages to plastic parts caused by aggressive cleaning agents, DMG recommends to follow these instructions:

CLEANING INSTRUCTIONS

Clean the part with cotton rug and warm water before applying the cleaning product.

Use PH-neutral cleaning products only (including aromatised ones).

Dilute the cleaning product in warm water and apply using a wet cotton rug.

Grease, glue and paint may be removed with ethylic alcohol or isopropilic alcohol after the part has been cleaned with a wet rug and warm water.

Download

| Reference | Version | Link |

|---|---|---|

| 1.0 (current version) | Download PDF (English) | |