(v 1.8)

Sistema completo per ascensori

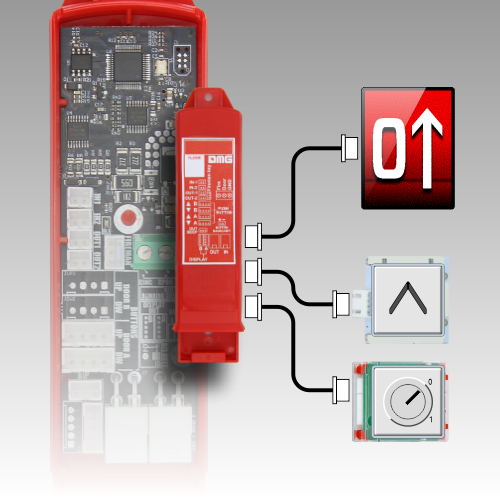

- Scheda madre: funzioni principali, modulo di programmazione, led diagnostici, descrizione dei connettori.

- Menu di programmazione e modifica dei parametri del sistema

- VVVF Frenic Lift Setting

- Istruzioni per l'aggiornamento del software

Approfondimenti

Qui troverete l'elenco dei difetti con la loro descrizione, la causa e il rimedio.

Connettività e applicazione Fusion

Fusion è la nuova app sviluppata da DMG per consentire il monitoraggio locale e remoto del Pitagora 4.0 da smartphone o PC.

Funzionamento del servizio antincendio

Qui è possibile impostare i parametri per le operazioni antincendio secondo 5 casi diversi.

Le procedure per i test di sicurezza del sistema e per la misurazione spazio-temporale del movimento della cabina dell'ascensore sono descritte qui.

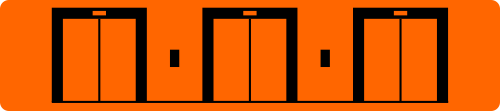

Il pannello di controllo Pitagora 4.0 può gestire sistemi multiplex fino a 6 ascensori.

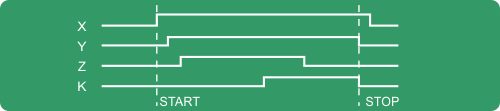

Diagrammi temporali di comandi di marcia secondo il tipo di sistema.

Download

Potete scaricare qui le pagine web DIDO del sistema Pitagora 4.0

È possibile scaricare qui le dichiarazioni di conformità