1) Switch the lift into INSPECTION mode

2) Motor Parameter check

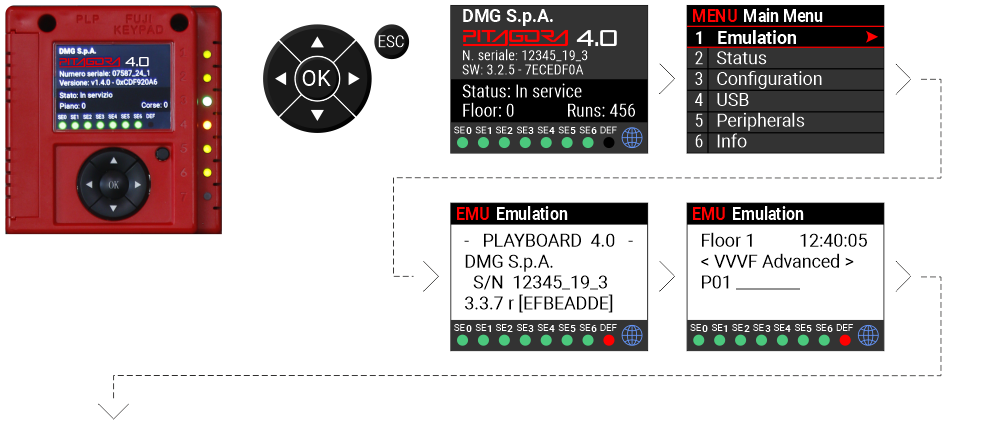

From the main menu, access the Emulation menu.

Main Menu > Emulation > VVVF Advanced

GEARED motors

Parameters normally pre-set if specified when ordering.

| VVVF Fuji parameter | Description | Note |

|---|---|---|

| P01 – Motor poles | Enter the number of motor poles | |

| F03 – Maximum speed | Enter the maximum motor speed (RPM) | |

| F04 – Rated Speed | Enter the rated motor speed (Hz) | |

| F05 – Rated Voltage | Enter the rated motor Voltage | |

| P03 – Motor Rated Cur | Enter the rated current intensity of the machine | |

| P02 – Motor Rated Cap | Enter the rated power of the machine | |

| C11 – High speed | Set high speed C11 (value specified on the motor nameplate) | Only with magnetic sensors counting system (FAI / FAS) |

| C10 – Middle speed | Set inspection/intermediate speed C10 | as above |

| C07 – Creep speed | Set low speed C07 (typically 10% of C11) | as above |

| L01 – PG select | Set the motor encoder type | Closed loop systems only |

| L02 – PG resolution | Set the motor encoder resolution (typically 1024) | as above |

| P04 – Motor Autotuning 3 = Open loop 2 = Closed loop 1= Motors with unknown data |

GEARLESS motors

Parameters normally pre-set if specified when ordering.

| VVVF Fuji parameter | Description | Note |

|---|---|---|

| P01 – Motor poles | Enter the number of motor poles | |

| F03 – Maximum speed | Enter the maximum motor speed (RPM) | |

| F04 – Rated Speed | Enter the rated motor speed (Hz) | |

| F05 – Rated Voltage | Enter the rated motor Voltage | |

| P08 – M-%X | Set the value “10%” | Confirm the proposed value |

| P07 – M-%R1 | Set the value “5%” | as above |

| P06 – M-No-load Curr. | Set the value “0 Ampere” | as above |

| P03 – Motor Rated Cur | Enter the rated current intensity of the machine | |

| P02 – Motor Rated Cap | Enter the rated power of the machine | |

| C11 – High speed | Set high speed C11 (value specified on the motor nameplate) | Only with magnetic sensors counting system (FAI / FAS) |

| C10 – Middle speed | Set inspection/intermediate speed C10 | as above |

| C07 – Creep speed | Set low speed C07 (typically 10% of C11) | as above |

| L01 – PG select | Set the motor encoder type | Closed loop systems only |

| L02 – PG resolution | Set the motor encoder resolution (typically 1024) | as above |

| L03 – P.P. Tuning 4 = Static tuning (depending on the motor type 5 = Dynamic tuning (free from ropes) |

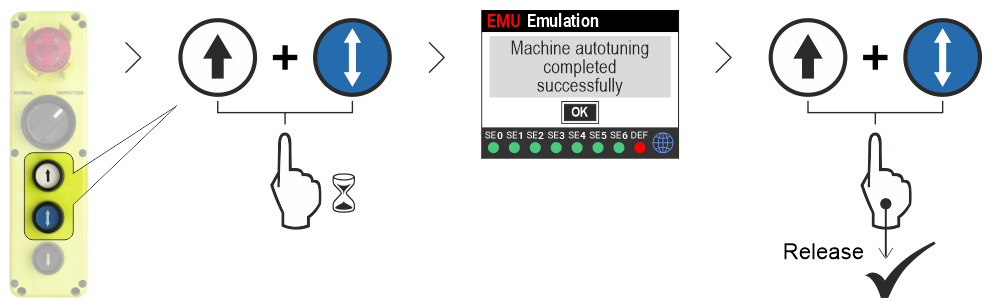

3) Closing of Self-learning phase

Pole tuning troubleshooting

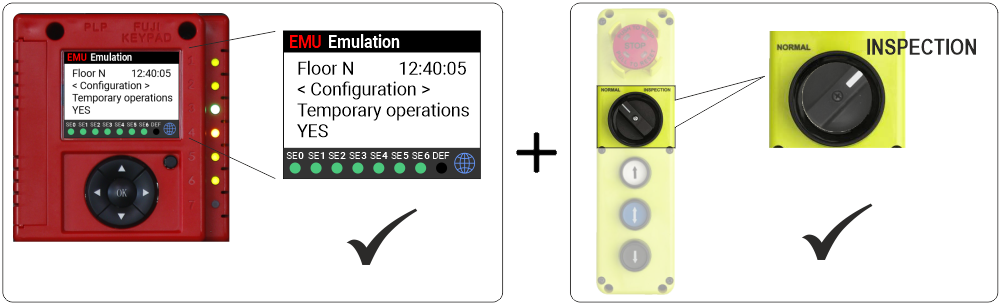

Check that the lift is in temporary operations.

Main Menu > Emulation > Configuration > Temporary operations > YES

Try moving the cabin UP/DOWN manually.

If the lift does not react accordingly, follow the instructions below.

Change H190 value from 1 to 0

| Error code | Typical VVVF errors after failed Autotuning (Menu -> VVVF Advanced) |

|---|---|

| 52 – OS | Overspeed |

| 52 – ErE | Speed mismatch (speed deviation excess) |

| 52 – OI1 | Motor overload |

| 52 – OLU | Inverter overload |

| 52 – Oc1 | Overcurrent during acceleration |

| 52 – Oc2 | Overcurrent during deceleration |

| 52 – Oc3 | Overcurrent during constant speed |

Perform the following checks

Problem solved

Swap values of parameters E98 – E99

Problem solved

- Verify that L80=1 and L82=0,2

- Check wiring of brakes

- Check brake tension

“ENABLE” first, then “FORWARD”

or “REVERSE” (based on direction)

- Verify color and sequence of encoder wiring

- Connect cable shield to “CM” terminal of the board