Emergency operations requiring the intervention of a lift operator

The Emergency Operations are specific procedures to be adopted to manually or automatically move the cabin and evacuate people trapped following a blockage of the elevator outside the door zone. The procedures differ depending on the technology of the system (electrical or hydraulic) and must be carried out by qualified technicians or adequately trained personnel.

Emergency operations for VVVF lifts

ELECTRICAL EMERGENCY OPERATION (EN81-20/50 – § 5.12.1.6)

The emergency maneuver is always present in traction electric lift that comply with the EN81-20 and EN81-1 standards. It is used when there is a need to move the cabin, both in emergency situations and during dynamic tests (grip tests, parachute tests, shock absorber tests, etc.).

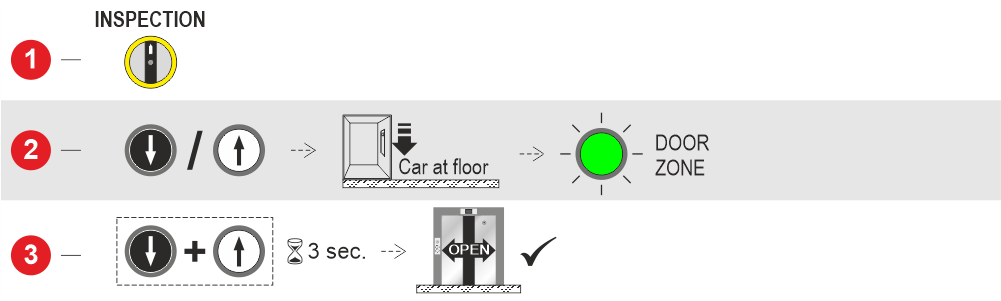

The procedure for activating this maneuver is the following:

1 – Set the Mode Switch to “INSPECTION”.

2 – Constantly press the “Up” or “Down” buttons. The cabin moves in the desired direction.

3 – Press the “Up” and “Down” buttons simultaneously for 3 seconds to open the cabin doors.

To reset the system, set the switch to “Normal”.

Note: when in “INSPECTION” mode, all cabin movements except those controlled by this maneuver, and all calls to the floors, including remote devices, are excluded.

In the case that either the car top box or pit box switch is in “INSPECTION” mode, this Electrical Manoeuvre is inhibited (priority is given to the inspection button panels in the Shaft).

MANUAL RESCUE OPERATION

The manual rescue maneuver, mandatory for all EN81-20 systems, allows the cabin to be moved manually towards the nearest floor using the difference in weight between the counterweight and the cabin. This maneuver is used in all cases of cabin blockage outside the floor, even in the event of a system blackout, to quickly evacuate trapped people. All Pitagora 4.0 MRL and Machine Room controllers are equipped with an embedded UPS unit that re-powers the motherboard in emergency mode and allows the cabin to be brought up/down to the most favorable floor.

Note: this rescue maneuver must be performed by skilled technicians and is possible only if no blocking faults are active.

The procedure for activating the unbalancing rescue maneuver is different for gearless 81.20 and geared 81.1/81.20 lifts:

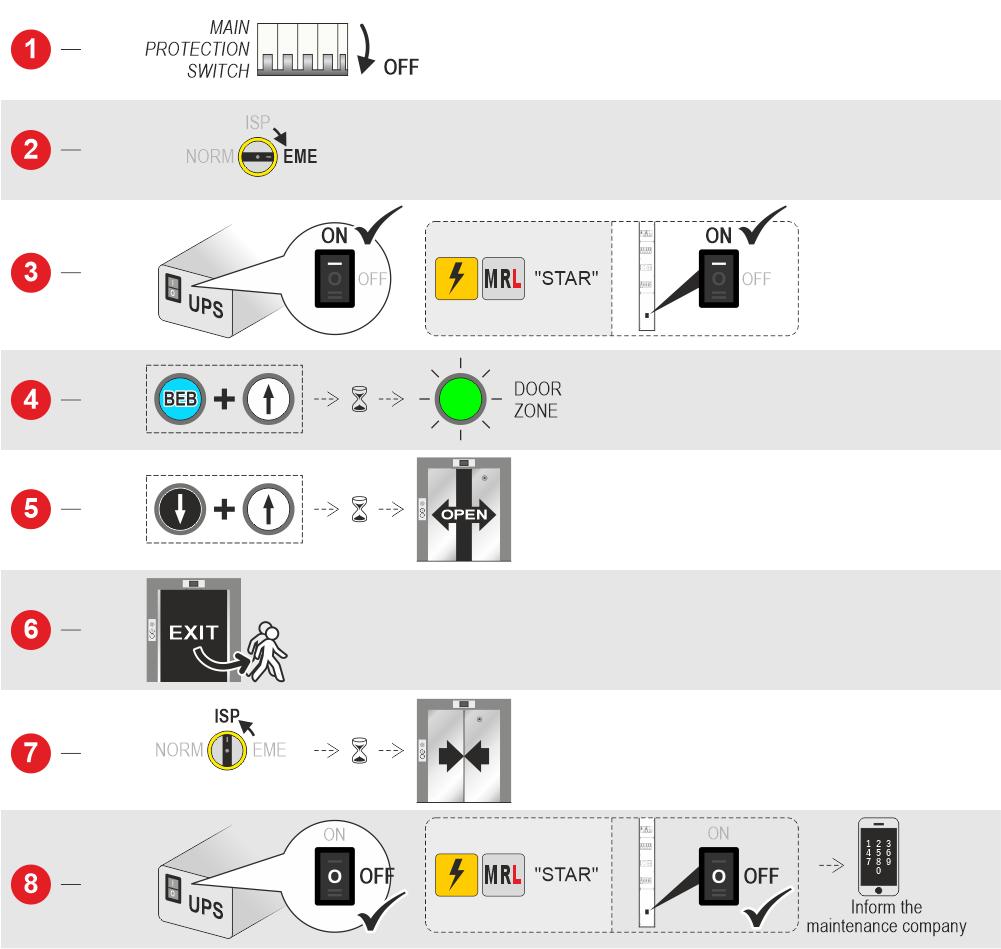

Gearless drive (MR and MRL traction lifts)

1 – Set the main power switch to “OFF”

2 – Set the Mode Switch to “EME”

3 – Turn on the UPS unit inside the panel

4 – Press the “Enable” and “Up” buttons constantly. The cabin moves by unbalancing at a controlled speed. The “Door Zone” indicator lights up to indicate that the cabin has reached the floor

5 – Press the “Up” and “Down” buttons constantly to open the cabin doors

6 – Free any trapped people by unlocking the floor doors

7 – Set the Mode Switch to “Inspection”

8 – Turn off the UPS

Geared drive (MR traction lifts)

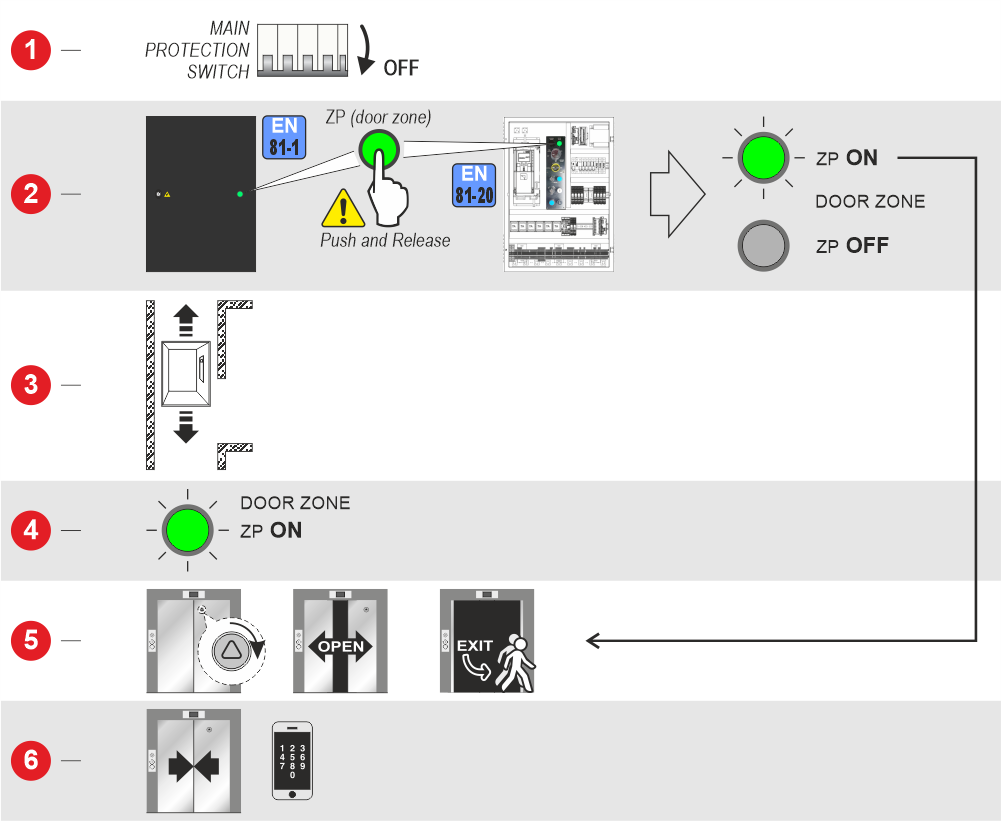

1 – Set the main power switch to “OFF”

2 – Check the door zone indicator (on the cabinet door for EN81-1 lifts, on the inspection panel for EN81-20 ones). If the light is on (cabin in door zone), go to point 5. Otherwise, go to point 3.

Attention: After pressing the ZP button you have 1 hour (default) to carry out the maneuver. If the procedure takes longer, press it again.

3 – Open the brake using the appropriate lever on the geared drive and at the same time turn the handwheel in the direction of easiest movement or least effort. Move the cabin until it reaches the nearest floor (green light on)

4 – Stop the movement when the green “Door zone” light comes on

5 – Unlock the cabin doors

6 – During and after the manual maneuver, make sure that all the landing doors are closed and

locked and inform the maintenance company. If the system is to remain out of service for more

than 14 hours, move the car to the lowest floor.

Emergency operations for Hydraulic lifts

MANUAL RESCUE OPERATION

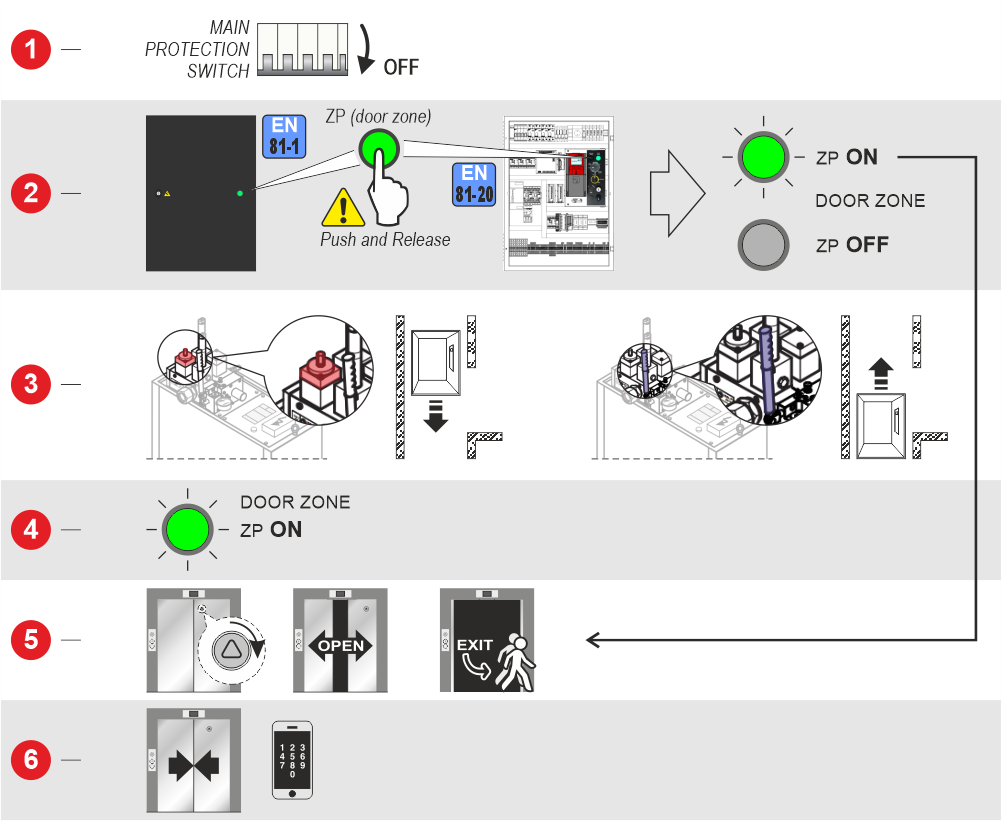

In hydraulic lifts, the manual rescue maneuver is always present, regardless of the regulations. The procedure for activating the manual emergency maneuver is as follows:

1 – Set the main power switch to “OFF”

2 – Check the door zone indicator (on the cabinet door for EN81-1 lifts, on the inspection panel for EN81-20 ones). If the light is on (cabin in door zone), go to point 5. Otherwise, go to point 3.

Attention: After pressing the ZP button you have 1 hour (default) to carry out the maneuver. If the procedure takes longer, press it again.

3 – Press and hold the button on the hydraulic unit to move the cabin down. Use the hand pump lever to move the cabin up.

4 – Stop the movement when the green “Door zone” light comes on

5 – Unlock the cabin doors

6 – During and after the manual maneuver, make sure that all the landing doors are closed and

locked and inform the maintenance company. If the system is to remain out of service for more

than 14 hours, move the car to the lowest floor.

Automatic return to floor systems

The second value of the EME Delay parameter in the Signals menu indicates the delay in starting the emergency manoeuvre, i.e. the delay between the mains failure signal (IEME) and the activation of the output (OEME) before the system switches to automatic emergency mode.

VVVF lifts

Type A – Automatic return to nearest floor – Automatic Emergency VVVF EN81-20/81-1 with external UPS

The automatic return system (automatic emergency) to the nearest floor requires that the control panel, following a blackout or brief absence of power, automatically returns the cabin to the nearest floor, without intervention by third parties.

The Pitagora 4.0 control panel, if equipped with this option, is set up with an external UPS sized according to the size of the inverter. The control panel, once it has entered emergency mode and before starting to move the cabin towards the floor, performs a check to understand the favorable direction (i.e. it identifies the direction in which the inverter supplies less current to the motor and therefore where there is less absorption towards the UPS).

This is because the UPS is sized to make a short run and therefore has limited autonomy. Once it reaches the floor, the control panel will open the doors to let the trapped people out and close them again. Once the maneuver is finished, the control panel and the UPS will switch off after a pre-set time of 5 minutes.

The panel and UPS will resume normal operation once power is restored.

Type B – Automatic return to nearest floor – Integrated Emergency GEARLESS EN81-20

The Pitagora 4.0 EN81-20 control panel, if combined with a Gearless motor, provides an integrated maneuver in the event of a blackout using the device that allows manual maneuvering due to unbalance already present in the control panel. The automatic return system (automatic emergency) to the nearest floor provides that the control panel, following a blackout or a brief absence of power, autonomously brings the cabin back to the nearest floor in the favorable direction (depending on the load present in the cabin), with only the opening of the brakes and the speed control. The braking torque of motors of this type should guarantee a limited speed of movement, otherwise the panel keeps it under control with a modulation of the brakes until the nearest floor is reached. Once the floor is reached, the panel will open the doors to let the trapped people out and close them again. The panel will resume normal operation once the power is restored.

Type C – Automatic return to the preset floor – Automatic Emergency VVVF EN81-20/81-1 with external UPS

The automatic emergency maneuver to a pre-established floor requires that the control panel, following a blackout or a brief absence of power, returns the cabin to a pre-established floor. The control panel is equipped with an external UPS that is sized according to the system, given that it is necessary to take into account variants that can vary from system to system (motor power, shaft length, emergency speed, cabin weight, cabin capacity, etc.). The control panel, once it has entered emergency mode, will direct the cabin to the pre-established floor. Once it has reached the pre-established floor, the control panel will open the doors to allow the trapped people to exit and close them again. Once the maneuver is finished, the control panel and the UPS will switch off after a pre-established time of 5 minutes. The control panel and the UPS will resume normal operation once the power has been restored.

Type D – Evacuation maneuver specific to elevators on ships (RNO)

The evacuation takes place at the fire evacuation floor (without external UPS). For multiplex systems, one elevator is moved at a time.

Hydraulic lifts

The automatic emergency maneuver at the floor, in the case of hydraulic elevators, requires that the control panel, following a blackout or a brief absence of power, brings the cabin down to the lowest floor. The control panel is equipped with a small UPS to restart the peripherals of the control panel. The control panel must always also be equipped with the emergency buffer circuit.

The control panel, once it has entered emergency mode, begins to move the cabin towards the floor using the descent valve until it reaches the floor. Once the cabin reaches the floor, the control panel will open the doors to allow the trapped people to disembark and close them again. Once the maneuver is complete, the control panel and the UPS turn off. The control panel will resume normal operation once the power has been restored.