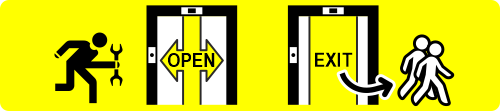

Door command

The door command board can command either one or two doors with alternative, selective or passage through opening. Output and inputs are available on the jst connectors on the TOC board and on APPO board (in the controller).

The doors can be automatic, semi-automatic or manual:

DOOR A

- ROA output (relay open door A) open collector max 24V 100mA

- RFA output (relay closing door A) open collector max 24V 100mA

- Input BRA (A oor opening button relay) closed to GND (NA) I = 5mA

- Input CEA (A door photocell) closed to GND (NA) I = 5mA

- Input FOA (A door opening limit) closed to GND (NA) I = 5mA

- Input FFA (A door closing limit) closed to GND (NA) I = 5mA

DOOR B

- ROB output (relay opening door B) open collector max 24V 100mA

- RFB output (relay closure door B) open collector max 24V 100mA

- Input BRB (B door opening button relay) closing to GND (NA) I = 5mA

- Input CEB (B door photocell) closing to GND (NA) I = 5mA

- Input FOB (B door opening limit) closing to GND (NA) I = 5mA

- Input FFB (B door closing limit) closing to GND (NA) I = 5mA

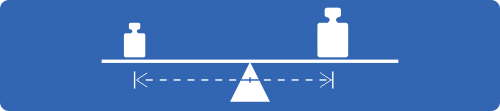

Weight load control

When COM input is active, floor reservation calls are neither recorded nor managed.

When SUR input is active the elevator car does not start and the acoustic signal in the elevator car is activated. The SUR signal is ignored while driving.

– Maximum load 630 Kg.

– Electric lift with VVVF Fuji LM2

– Gearless motor

– Direct or 2:1

The solution does not comply with the regulations (81.20 point 5.12.1.2.2) and therefore a risk analysis was carried out.

The function needs a Calibration procedure (See test 22)

– Adding panels, push buttons or flooring

– Addition of the compensation chain

Amigo emergency telephone

Visit the Amigo emergency telephone page to connect it to the Pitagora 4.0 system.

Link

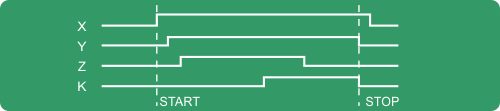

Elevator car Position / Speed Control with Motor Encoder

This control system can only be used on systems with inverter VVVF with a Gearless Motor.

Location, stop and deceleration are controlled by counting the pulses coming from the encoder of the motor. The counting of the pulses is suitably corrected (reset) by the reset signals at the top and bottom (AGB / AGH) and from the signal of door zone (ISO1).

The same J16 input connector is used to connect, with the appropriate cable, the encoder interface card, which is inside the FUJI inverter.

Parameter ”Count System” should be set as “engine encoder”. In menu choose 2048 number of pulses. Subsequently the dimensional parameters of the motor pulley and the type of pulling system should be inserted. Next the system asks to set the shaft length in order to set the correct sensitivity. Only after these steps are completed, Will it be possible to run the automatic floor levelling procedure.

Rollback control and ride comfort

When the Playboard controller is applied to installations equipped with closed loop gearless machines, comfort and precision can be optimized thus avoiding undesired effects such as rollback (typical of lifts with unbalanced load).

The following parameters can be adjusted to achieve optimal setting for your installation. It is suggested to follow the procedure from start to end in the proposed sequence.

| Parameter | Description | Default | Suggested Adjustments | |

|---|---|---|---|---|

| Gearless | Geared | |||

| H64 | Zero speed control time | 0,8 | 0,8 | Set value between 0,7 and 0,8 then increase to soften start phase ramp Important: In “Positioning” Menu : Delay DIR-BRK <= 0,2 s Delay BRK-S > H64 |

| L68 | RBC Proportional Gain (P constant) (specifies the P constant of the Automatic Speed Regulator to be used during RBC calculation time) | 1,8 | 10 | Motor overshoots: increase value by 0,25 Vibrations: decrease value by 0,25 |

| L69 | RBC Integral Time (I constant) (specifies the I constant of the Automatic Speed Regulator to be used during RBC calculation time) | 0,003 s | 0,010 s | Motor overshoots: decrease value by 0,001 Vibrations: increase value by 0,001 |

| L73 | Unbalanced load compensation (specifies the I constant of the Automatic Position Regulator to be used during RBC calculation time) | 0,5 | 0 | Motor overshoots: increase value by 0,50 Vibrations: decrease value by 0,50 |

| L82 | ON delay time (specifies the delay time during which the inverter main circuit is kept activated) | 0,2 s | 0,2 s | Larger Brakes: decrease value by 0,1 Smaller brakes: increase value by 0,1 |

Notes: L65 specifies whether to enable or disable the unbalanced load compensation (Rollback control). By default, it is set to 1 (Rollback control active). Speed is kept at zero when brakes are released to avoid rollback effect.

| Parameter | Description | Default | Suggested Adjustments | |

|---|---|---|---|---|

| Gearless | Geared | |||

| L24 | “S” Curve setting 6 | 25$ | 25% | Speed fluctuations: increase value by 5 |

| L36 | “P” Gain constant at high speed | 2 | 10 | Speed fluctuations increase value by 0,25 Vibrations: decrease value by 0,25 |

| L37 | “I” Time I constant at high speed | 0,100 s | 0,100 s | Speed fluctuations decrease 0,01 Vibrations: increase value by 0,01 |

Notes:

Increasing the P constant makes response from machinery faster but may cause overshooting or hunting in motor. Furthermore, due to resonance of machinery or overamplified noise, machinery or motor may produce vibration noise.

On the contrary, decreasing the P constant excessively delays response and may cause speed fluctuation in a long cycle, taking time to stabilize the speed.

“I” times values (L37 and L39) normally do not need to be changed, unless “P” gains are not enough to achieve optimal comfort. Setting a small “I” Time constant shortens the integration interval, providing a faster response. On the contrary, setting a large “I” Time constant lengthens it, having less effect on the ASR. This may help in case of resonance of machinery generating abnormal mechanical noise from the motor or gears.

| Parameter | Description | Default | Suggested Adjustments | |

|---|---|---|---|---|

| Gearless | Geared | |||

| E16 | Deceleration time # 9 (Last deceleration ramp) | 1,80 s | 1,80 s | Increase value by 0,5 to soften last ramp (max suggested value: 3 sec) |

| H67 | Stop Hold Time | 1,5 s | 1,5 s | Car unable to stay at floor: increase 0,25 Important: In “Positioning” Menu : Delay BRK-DIR <= 2,0 s Stopping Boost = 1% or 2% |

| L38 | “P” Gain constant at low speed | 2 | 10 | Car unable to stay at floor: increase 0,25 Vibrations: decrease value by 0,25 |

| L39 | I” Time I constant at low speed | 0,100 s | 0,100 s | Car unable to stay at floor: decrease value by 0,01 Vibrations: increase value by 0,01 |

| L83 | Brake Control (OFF delay time) (specifies the delay time between stop speed and deactivation of the brake signal) | 0,3 s | 0,1 s | Larger Brakes: decrease value by 0,1 Smaller brakes: increase value by 0,1 |

Notes: In order to let the inverter perform the stopping phase correctly, make sure that operating contactors open at least 2 sec after brake contactor. If operating contactors open in advance, a shock on the machine may be heard.

| Parameter | Description | Default | Suggested Adjustments |

|---|---|---|---|

| F24 | Starting speed holding time | 0,7 | Set value between 0,7 and 0,8 |

| H64 | Zero speed control time | 0 | Set value to 0 |

| E12 | Acceleration at high speed | 2 | Speed fluctuations: increase value by 0,25 |

| E13 | Acceleration at low speed | 2 | Motor stops: increase value by 0,25 |

| C07 | Creep Speed (5-10% of high speed) | Motor stops: increase value by 0,1 Vibrations: increase/decrease value by 0,1 |

|

| C11 | High Speed | See Nominal Value on the motor plate | If the elevator car is unable to keep floor level, make sure the low speed phase is performed correctly by reducing high speed C11 to half of its value to check that low speed is kept for few seconds, then slowly increase C11 |

UCM circuit

Connection to the circuit for UCM solution.

Pitagora 4.0 has own certified solutions for managing of UCM solution in lift installations.

The UCM system consists of three parts:

– Detector who detects an Unintended Cabine Movement.

– Actuator how the braking action is implemented

– Stopping Device what stops the cabin.

The Stopping Device must be a certified safety device and it is the installer’s responsibility to ensure the compatibility of the different elements of the UCM system.

For the functional verification of the entire system and the measurement of the spaces and intervention times, specific tests are provided to be carried out at the end of the assembly (see Test and measurements).

-) Central unit / valves configuration (see table 2)

-) UCM solution managed by controller

Table 1 – Monitor UCM

| Monitor UCM | Device / Hydraulic Control Unit | UCM Solution | Actuator | |

|---|---|---|---|---|

| Type | Time | |||

| No | Not present | No | - | |

| 1 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX | Yes | Safety Gear |

| 2 | 1,5 s | Controller = Brake monitor Movement with door open available only with Encoder ELGO LIMAX 33CP | Yes | A3 Certified Brakes |

| 3...17 | Do not use | |||

| 18 | 1,5 s | Brake monitor for Door opening enable (door opens only if brake is fall) | No | |

| 19 | 1,5 s | DMG UCM Circuit 4.0 (no brake monitor) Only for temporarly disabling of Brake switches monitor | No | |

| 20 | 1,5 s | DMG UCM Circuit 4.0 and Brake monitor | Yes | A3 Certified Brakes |

| 21 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Controller = Brake monitor | Yes | Safety Gear |

| 22 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin deactivation delay equal to the time for automatic return to the floor | Yes | Safety Gear |

| 23 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin deactivation delay equal to the time for automatic return to the floor Controller = Brake monitor | Yes | Safety Gear |

| 24 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin activation ED 100% | Yes | Safety Gear |

| 25 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin activation ED 100% Controller = Brake monitor | Yes | Safety Gear |

| 26...29 | Do not use | |||

| 30 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Without UCM / ELGO | |

| 31 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Yes = OSG A3 | Safety Gear |

| 32 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Yes = UCM 4.0 | Two valves |

| 33 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Without UCM / ELGO | Pawl device |

| 34 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | ||

| 35 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Without UCM / ELGO | |

| 36 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Yes = OSG A3 | Safety Gear |

| 37 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Yes = UCM 4.0 | Two valves |

| 38 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Without UCM / ELGO | Pawl device |

| 39 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | ||

| 40 | 1,5 s | GMV model NGV Central Unit | Without UCM / ELGO | |

| 41 | 1,5 s | GMV model NGV Central Unit | Yes = OSG A3 | Safety Gear |

| 42 | 1,5 s | GMV model NGV Central Unit | Yes = UCM 4.0 | Two valves |

| 43 | 1,5 s | GMV model NGV Central Unit | ||

| 44 | 1,5 s | GMV model NGV Central Unit | ||

| 45 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Without UCM / ELGO | |

| 46 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Yes = OSG A3 | Safety Gear |

| 47 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Yes = UCM 4.0 | Two valves |

| 48 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | ||

| 49 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | ||

| 50 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Without UCM / ELGO | |

| 51 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Yes = OSG A3 | Safety Gear |

| 52 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Yes = UCM 4.0 | Two valves |

| 53 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Without UCM / ELGO | Pawl device |

| 54 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | ||

| 55 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Without UCM / ELGO | |

| 56 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Yes = OSG A3 | Safety Gear |

| 57 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Yes = UCM 4.0 | Two valves |

| 58 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Without UCM / ELGO | Pawl device |

| 59 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | ||

| 60 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Without UCM / ELGO | |

| 61 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Yes = OSG A3 | Safety Gear |

| 62 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Yes = UCM 4.0 | Two valves |

| 63 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | ||

| 64 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | ||

| 65 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Without UCM / ELGO | |

| 66 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Yes = OSG A3 | Safety Gear |

| 67 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Yes = UCM 4.0 | Two valves |

| 68 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | ||

| 69 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | ||

| 70 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Without UCM / ELGO | |

| 71 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Yes = OSG A3 | Safety Gear |

| 72 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Yes = UCM 4.0 | Two valves |

| 73 | 1,5 s | Start Elevator unit 93/E-2DS (test) | ||

| 74 | 1,5 s | Start Elevator unit 93/E-2DS (test) | ||

| 75 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Without UCM / ELGO | |

| 76 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Yes = OSG A3 | Safety Gear |

| 77 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Yes = UCM 4.0 | Two valves |

| 78 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | ||

| 79 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | ||

| 80 | 1,5 s | GMV 3010 2CH (DSV A3 valve is optional, no test performed) | Without UCM / ELGO | |

| 81 | 1,5 s | GMV 3010 2CH (DSV A3 valve is optional, no test performed) | Yes = OSG A3 | Safety Gear |

| 82 | 1,5 s | GMV 3010 2CH (DSV A3 valve is optional, no test performed) | Yes = UCM 4.0 | Two valves |

| 83 | 1,5 s | GMV 3010 2CH (DSV A3 valve is optional, no test performed) | Without UCM / ELGO | Pawl device |

| 84 | 1,5 s | GMV 3010 2CH (DSV A3 valve is optional, no test performed) | ||

| 85 | 1,5 s | GMV 3010 2CH + DSV A3 (test performed) | Without UCM / ELGO | |

| 86 | 1,5 s | GMV 3010 2CH + DSV A3 (test performed) | Yes = OSG A3 | Safety Gear |

| 87 | 1,5 s | GMV 3010 2CH + DSV A3 (test performed) | Yes = UCM 4.0 | Two valves |

| 88 | 1,5 s | GMV 3010 2CH + DSV A3 (test performed) | Without UCM / ELGO | Pawl device |

| 89 | 1,5 s | GMV 3010 2CH + DSV A3 (test performed) | ||

| UCM | Installation Type | Reduced | Door Contacts | |||

|---|---|---|---|---|---|---|

| Type | Time | PIT | HEAD | Monostable | Bistable | |

| No | EN 81.1 / EN 81.2 | |||||

| 1 | 1,5 s | EN 81.1 / EN 81.2 with Bypass door circuit With SM1 Safety module (Bypass’ knob opens safety chain) | ||||

| 2 | 1,5 s | EN 81.1 / EN 81.2 with Door Bypass Circuit Without SM1 Safety module (Bypass’ knob opens REV input) | ||||

| 3 | 1,5 s | EN 81.1 / EN 81.2 With management of Norme 511 (Light and Buzzer) | X | |||

| 4 | 1,5 s | EN 81.1 / EN 81.2 with Door Bypass Circuit With SM1 Safety module (Bypass’ knob opens safety chain) With management of Norme 511 (Light and Buzzer) | X | |||

| 5 | 1,5 s | EN 81.1 / EN 81.2 with Door Bypass Circuit Without SM1 Safety module (Bypass’ knob opens REV input) With management of Norme 511 (Light and Buzzer) | X | |||

| 6 | 1,5 s | EN 81.20 with monostable contacts Pit Access control With management of Norme 511 (Light and Buzzer) | X | |||

| 7 ... 13 | Not use | |||||

| 14 | 1,5 s | EN 81.20 with monostable contacts No protection in head. Custom solution with risk analisys | X | X(*) | ||

| 15 | 1,5 s | EN 81.20 with monostable contacts Manual Protection Device in PIT | X | X(*) | ||

| 16 | 1,5 s | EN 81.20 with monostable contacts Manual Protection Device in PIT (under the cabine) and No protection in head. Custom solution with risk analisys | X | X | ||

| 17 | 1,5 s | EN 81.20 / 21 with bistable contacts No protection in head. Custom solution with risk analisys | X | X(*) | X | |

| 18 | 1,5 s | EN 81.20 / 21 with bistable contacts Manual Protection Device in PIT | X | X(*) | ||

| 19 | 1,5 s | EN 81.20 / 21 with bistable contacts Manual Protection Device in PIT (under the cabine) and No protection in head. Custom solution with risk analisys | X | X | X | |

| 20 | 1,5 s | EN 81.20 with monostable contacts Pit Access control | X(*) | |||

| 21 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device ELGO + OSG A3 (type 1) | X | X(*) | X | |

| 22 | 1,5 s | EN 81.20 / 21 with bistable contacts Manual Protection Device in PIT | X | X(*) | X | |

| 23 | 1,5 s | EN 81.20 / 21 with bistable contacts Manual Protection Device in PIT | X | X(*) | ||

| 24 | 1,5 s | EN 81.20 / 21 with bistable contacts Manual Protection Device in PIT | X | X | X | |

| 25 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SHI Technolift | X | X(*) | X | |

| 26 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SHI Technolift | X | X(*) | ||

| 27 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SHI Technolift | X | X | X | |

| 28 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device OSG A3 Montanari | X | X(*) | X | |

| 29 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device OSG A3 Montanari | X | X(*) | ||

| 30 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device OSG A3 Montanari | X | X | X | |

| 31 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device ELGO + OSG A3 (type 2) | X | X | X | |

| 32 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device AMI 100 CMF | X | X(*) | X | |

| 33 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device AMI 100 CMF | X | X(*) | ||

| 34 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device AMI 100 CMF | X | X | X | |

| 35 | 1,5 s | EN 81.20 / 21 with monostable contacts Manual Protection Device in PIT | X | X | ||

| 36 | 1,5 s | EN 81.20 / 21 with monostable contacts Manual Protection Device in PIT | X | X(*) | ||

| 37 | 1,5 s | EN 81.20 / 21 with monostable contacts Manual Protection Device in PIT | X | X | X | |

| 38 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SHI Technolift | X | X | ||

| 39 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SHI Technolift | X | X(*) | ||

| 40 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SHI Technolift | X | X | X | |

| 41 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device OSG A3 Montanari | X | X | ||

| 42 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device OSG A3 Montanari | X | X(*) | ||

| 43 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device OSG A3 Montanari | X | X | X | |

| 44 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device AMI 100 CMF | X | X | ||

| 45 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device AMI 100 CMF | X | X(*) | ||

| 46 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device AMI 100 CMF | X | X | X | |

| 47 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SDH Technolift | X | X(*) | X | |

| 48 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SDP Technolift | X | X(*) | ||

| 49 | 1,5 s | EN 81.20 / 21 with bistable contacts Protection Device SDH + SDP Technolift | X | X | X | |

| 50 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SDH Technolift | X | X | ||

| 51 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SDP Technolift | X | X(*) | ||

| 52 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device SDH + SDP Technolift | X | X | X | |

| 53 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X(*) | X | |

| 54 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X(*) | ||

| 55 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X | X | |

| 56 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X | ||

| 57 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X(*) | ||

| 58 | 1,5 s | EN 81.20 / 21 with monostable contacts Protection Device ESG WITTUR | X | X | X | |

X(*) = Means that contact is needed only at the lowest floor door.

A non-exhaustive list of the types of UCM systems and solutions most used are shown in the following table, where different applicable solutions are highlighted, each of which has its own dedicated interface and programming circuit. The interfacing with the listed devices is carried out according to the specifications indicated in the manuals of the relevant manufacturers.

When the absolute positioning system ELGO LIMAX 33CP is provided (see the relevant page), its certified UCM function is used.

| System type | UCM system | ||

|---|---|---|---|

| Detector | Actuator | Stopping device | |

| Electric lift. No maneuvers with open doors. | Not required. (only brakes’ monitor) | ||

| Electric lift. Maneuvers with open doors. | Pitagora 4.0 | Brake controls interruption (safety chain open) | Brakes (*) |

| Electric lift. Maneuvers with open doors with ELGO LIMAX 33CP | ELGO LIMAX 33CP | ||

| Electric lift. Over Speed Governor with anti drift device (**) | Pitagora 4.0 | Power interruption of the pin. | Safety Gear |

| Electric lift. Over Speed Governor with anti drift device (**) with ELGO LIMAX 33CP | ELGO LIMAX 33CP | ||

| Hydraulic lift with double descent valve | Pitagora 4.0 | Valve controls interruption (safety chain open) | Valves (***) |

| Hydraulic lift with double descent valve with ELGO LIMAX 33CP | ELGO LIMAX 33CP | ||

| Hydraulic lift with electronic valve management (certified control unit) | Pitagora 4.0 | ||

| Hydraulic lift with electronic valve management (certified control unit) with ELGO LIMAX 33CP | ELGO LIMAX 33CP | ||

(*) solution applicable exclusively for double brakes certified as UCM stop element according to EN 81-20 5.6.7.3 and 5.6.7.4 (Geraless motors or motors with gearbox and slow shaft brake).

(**) UCM certified limiters with anti-drift pin (for example Montanari RQxxx-A, PFB LKxxx with LSP coil, or similar devices).

(***) Valves in series certified as stop element UCM according to EN 81-20 5.6.7.3 and 5.6.7.4