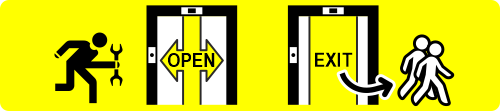

The UCMP (Unintended Car Movement Protection) device is a protection system against uncontrolled movements of the lift cabin. It is mandatory for all systems that comply with the EN81-20 and EN81-1/2 + A3 (Amendment A3) standards.

For traction lifts that do not have open-door maneuvers and that have a certified stopping element (double brake on the motor drive), the simple monitoring of both braking elements is considered sufficient. In the case of geared motors, a braking element that acts on the pulley shaft (slow shaft) must be present.

For pre-A3 EN 81.1/2 lifts, UCMP protection is not mandatory. For Italy, the 10411 code indicates when UCMP solutions must be introduced in the case of modernizations of existing lifts.

UCMP systems are composed of 4 main elements:

Detector: detects the exit of the cabin from the door unlocking area in the absence of commands from the control panel.

Controller: activates the cabin stopping device when the detector is triggered

Stopping device: keeps the cabin still. Not generally supplied by the controller manufacturer.

Monitoring device: verifies the correct functioning of the stopping device.

It is the installer’s responsibility to evaluate the compatibility between the different elements and compliance with regulatory requirements and in particular the cabin stop distance.

The UCMP solutions offered with the Pitagora 4.0 traction controllers depend on the type of positioning system and on the presence / absence of open-door maneuvers (relevelling or advance door opening).

The different solutions are factory-programmed via the parameter D17-Monitor UCM of the Special Functions Menu of the Pitagora 4.0. The list of applicable values is the following:

| Monitor UCM | Device / Hydraulic Control Unit | UCM Solution | Actuator | |

|---|---|---|---|---|

| Type | Time | |||

| No | Not present | No | - | |

| 1 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX | Yes | Safety Gear |

| 2 | 1,5 s | Controller = Brake monitor Movement with door open available only with Encoder ELGO LIMAX 33CP | Yes | A3 Certified Brakes |

| 3...17 | Do not use | |||

| 18 | 1,5 s | Brake monitor for Door opening enable (door opens only if brake is fall) | No | |

| 19 | 1,5 s | DMG UCM Circuit 4.0 (no brake monitor) Only for temporarly disabling of Brake switches monitor | No | |

| 20 | 1,5 s | DMG UCM Circuit 4.0 and Brake monitor | Yes | A3 Certified Brakes |

| 21 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Controller = Brake monitor | Yes | Safety Gear |

| 22 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin deactivation delay equal to the time for automatic return to the floor | Yes | Safety Gear |

| 23 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin deactivation delay equal to the time for automatic return to the floor Controller = Brake monitor | Yes | Safety Gear |

| 24 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin activation ED 100% | Yes | Safety Gear |

| 25 | 1,5 s | Overspeed Governor OSG A3 Montanari RQ-AXXX Pin activation ED 100% Controller = Brake monitor | Yes | Safety Gear |

| 26...29 | Do not use | |||

| 30 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Without UCM / ELGO | |

| 31 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Yes = OSG A3 | Safety Gear |

| 32 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | Yes = UCM 4.0 | Two valves |

| 33 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | ||

| 34 | 1,5 s | Hydro Central Unit with Electromechanical valves (A3 second down valve is optional, no test performed) | ||

| 35 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Without UCM / ELGO | |

| 36 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Yes = OSG A3 | Safety Gear |

| 37 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | Yes = UCM 4.0 | Two valves |

| 38 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | ||

| 39 | 1,5 s | Hydro Central Unit with Electromechanical valves + A3 valve (test) | ||

| 40 | 1,5 s | GMV model NGV Central Unit | Without UCM / ELGO | |

| 41 | 1,5 s | GMV model NGV Central Unit | Yes = OSG A3 | Safety Gear |

| 42 | 1,5 s | GMV model NGV Central Unit | Yes = UCM 4.0 | Two valves |

| 43 | 1,5 s | GMV model NGV Central Unit | ||

| 44 | 1,5 s | GMV model NGV Central Unit | ||

| 45 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Without UCM / ELGO | |

| 46 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Yes = OSG A3 | Safety Gear |

| 47 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | Yes = UCM 4.0 | Two valves |

| 48 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | ||

| 49 | 1,5 s | GMV model NGV A3 Central Unit (RDY – RUN signals monitor) | ||

| 50 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Without UCM / ELGO | |

| 51 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Yes = OSG A3 | Safety Gear |

| 52 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | Yes = UCM 4.0 | Two valves |

| 53 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | ||

| 54 | 1,5 s | Bucher Electronic unit LRV + NTA-2 (A3 second down valve is optional, no test performed) | ||

| 55 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Without UCM / ELGO | |

| 56 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Yes = OSG A3 | Safety Gear |

| 57 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | Yes = UCM 4.0 | Two valves |

| 58 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | ||

| 59 | 1,5 s | Bucher Electronic unit LRV + NTA-2 + DSV A3 (test) | ||

| 60 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Without UCM / ELGO | |

| 61 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Yes = OSG A3 | Safety Gear |

| 62 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | Yes = UCM 4.0 | Two valves |

| 63 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | ||

| 64 | 1,5 s | Bucher Electronic unit i-Valve / iCON-2 (SMA monitor signal) | ||

| 65 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Without UCM / ELGO | |

| 66 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Yes = OSG A3 | Safety Gear |

| 67 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | Yes = UCM 4.0 | Two valves |

| 68 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | ||

| 69 | 1,5 s | Start Elevator unit 93/E-2DS (no test performed) | ||

| 70 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Without UCM / ELGO | |

| 71 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Yes = OSG A3 | Safety Gear |

| 72 | 1,5 s | Start Elevator unit 93/E-2DS (test) | Yes = UCM 4.0 | Two valves |

| 73 | 1,5 s | Start Elevator unit 93/E-2DS (test) | ||

| 74 | 1,5 s | Start Elevator unit 93/E-2DS (test) | ||

| 75 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Without UCM / ELGO | |

| 76 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Yes = OSG A3 | Safety Gear |

| 77 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | Yes = UCM 4.0 | Two valves |

| 78 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | ||

| 79 | 1,5 s | ALGI Electronic Unit AZRS 2.0 | ||

UCMP solutions for traction lifts

1) Brake monitoring (Q40.UCFR)

This basic UCMP solution can only be applied to EN81.20 traction lifts with either gearless or geared drives equipped with double certified brakes. For traction geared machines, the two braking elements must be applied to the pulley shaft (slow shaft).

In case of failure of one of the brakes, the Pitagora 4.0 controller just stops the cabin at the next floor and activates Fault 53.2 (error occurred when the cabin is stopped at floor) or 53.3 (error occurred when the cabin is travelling). All calls are canceled until the correct functioning of brakes is restored. The Error 53 requires a specific reset procedure.

As UCM protection solution, the brake monitoring is applicable only to lifts which does not feature open door maneuvers (relevelling or advance door opening). In these latter cases, other UCMP solutions must be in place.

2) DMG UCMP Solution

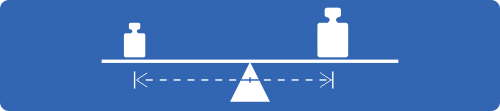

The standard UCMP solution by DMG is based on the use of the DMG Encoder system (rope-and-pullley Encoder), the ZP detectors (UCM Detector) in conjunction with the SM2 safety device (UCM Controller) included in the Q40.UCMP package.

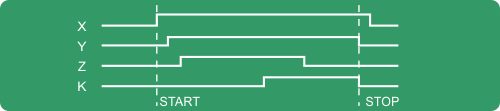

The certified SM2 safety module (STEM NC82) is connected to two safety relays connected in series (RUCM1 and RUCM2) which operate the motor contactors. If the system detects an unintended movement of the cabin outside of the door zone, the safety circuit promptly opens the relays which either cut the supply to the brake contactors or activate the external stopping device. Tests and measurements (See Tests #1 and #2 on https://dido.dmg.it/it/knowledge-base/test-p40/ ) indicate that the total reaction time of the circuit is less than 22ms.

In case of UCMP activation or faults in the UCM monitoring devices of traction lifts, Faults 53.100 to 53.240 are activated. The cabin is immediately blocked, and all calls are canceled. The Error 53 requires a specific reset procedure (“Error UCM” in the Playpad “Error” Menu).

The DMG UCMP solution is suitable for all traction lifts. If the traction machine is equipped with double certified brakes, the UCM Stopping Device is simply the machine brake itself. In all other cases (non-certified traction machines), the stopping device must be – for example – the A3 speed limiter.

The following set of parameters must be enabled in the Special Functions Menu of the PlayPad:

| Parameter | Values |

|---|---|

| Monitor UCM | See table |

3) ELGO Safe UCMP Solution

The advanced UCMP solution offered by DMG is based on the use of the ELGO Limax Safe Absolute Encoder which is a SIL3 safety device and therefore acts as both UCM Detector and UCM Controller (the two safety relays are integrated into the Encoder).

If the system detects an unintended movement of the cabin outside of the door zone, the brake contactors are immediately activated (or the external stopping device is activated via the eSGC output of the Limax encoder) .Tests and measurements (See Tests #10 and #11 on https://dido.dmg.it/it/knowledge-base/test-p40/ ) indicate that the total reaction time of the circuit is less than 45ms.

In case of UCMP activation or faults in the UCM monitoring devices of traction lifts, Faults 53.204 to 53.240 are activated. The cabin is immediately blocked, and all calls are canceled. The Error 53 requires a specific reset procedure (“Error UCM” in the Playpad “Error” Menu). Also, Error 60.24 or 60.254 are activated (ELGO Limax specific faults).

If the traction machine is equipped with double certified brakes, the UCM Stopping Device is simply the machine brake itself. In all other cases (non-certified traction machines), the stopping device must be – for example – the A3 speed limiter, enabled by the specific eSGC output of the Elgo Limax encoder, properly programmed.

The following set of parameters must be enabled in the Special Functions Menu of the PlayPad:

| Parameter | Values |

|---|---|

| Monitor UCM | See table |

UCMP solutions for hydraulic lifts

1) DMG UCMP Solution

The standard UCMP solution by DMG is based on the use of the DMG Encoder system (rope-and-pullley Encoder), the ZP detectors (UCM Detector) in conjunction with the SM2 safety device (UCM Controller) included in the Q40.UCMP package.

The certified SM2 safety module (STEM NC82) is connected to two safety relays connected in series (RUCM1 and RUCM2) which operate the oil motor contactors. If the system detects an unintended movement of the cabin outside of the door zone, the safety circuit promptly opens the relays which either cut the supply to the valve contactors or activate the external stopping device. Tests and measurements (See Tests #1 and #2 on https://dido.dmg.it/it/knowledge-base/test-p40/ ) indicate that the total reaction time of the circuit is less than 22ms.

In case of UCMP activation or faults in the UCM monitoring devices of hydro lifts, Faults 53.4 to 53.15 are activated. The cabin is immediately blocked, and all calls are canceled. The Error 53 requires a specific reset procedure (“Error UCM” in the Playpad “Error” Menu). The DMG UCMP solution is suitable for all hydraulic lifts. If the oil pump unit is equipped with double certified valves, the UCM Stopping Device is simply the valve itself. In all other cases (non-certified hydro machines), the stopping device must be – for example – the A3 speed limiter.

2) ELGO Safe UCMP Solution

The advanced UCMP solution offered by DMG is based on the use of the ELGO Limax Safe Absolute Encoder which is a SIL3 safety device and therefore acts as both UCM Detector and UCM Controller (the two safety relays are integrated into the Encoder).

If the system detects an unintended movement of the cabin outside of the door zone, the valve contactors are immediately activated (or the external stopping device is activated via the eSGC output of the Limax encoder). Tests and measurements (See Tests #10 and #11 on https://dido.dmg.it/it/knowledge-base/test-p40/ ) indicate that the total reaction time of the circuit is less than 45ms.

In case of UCMP activation or faults in the UCM monitoring devices of hydraulic lifts, Faults 53. 4 to 53.15 are activated. The cabin is immediately blocked, and all calls are canceled. The Error 53 requires a specific reset procedure (“Error UCM” in the Playpad “Error” Menu). Also, Error 60.24 or 60.254 are activated (ELGO Limax specific faults).

If the oil pump unit is equipped with double certified valves, the UCM Stopping Device is simply the machine valve itself. In all other cases (non A3-certified oil uniits), the stopping device must be – for example – the A3 speed limiter, enabled by the specific eSGC output of the Elgo Limax encoder, properly programmed.