List of faults with their description, cause and remedy.

| This symbol means a blocking fault: switch off main power and then switch it on again to put the lift back in service. |

1) – Reset

Description (and cause)

Power supply: the controller was restarted. For informational purpose only.

Furthermore, if there are devices that require a restart, it can present itself with the following specific codes.

Cod.9: 9 months without power cycle reset, lift continues to operate.

Cod.12: 12 months without power cycle reset, lift is out of service. Must be executed a power restart

Remedy

Cod.9 / 12 are present only in case of LM2 inverter or LIMAX3CP. Power restart is requested from these devices.

Power supply: the controller was restarted. For informational purpose only.

Furthermore, if there are devices that require a restart, it can present itself with the following specific codes.

Cod.9: 9 months without power cycle reset, lift continues to operate.

Cod.12: 12 months without power cycle reset, lift is out of service. Must be executed a power restart

Remedy

Cod.9 / 12 are present only in case of LM2 inverter or LIMAX3CP. Power restart is requested from these devices.

2) – Contactors blocked

Description (and cause)

One or more NC contacts associated to the power contactors and connected in series on the input CCO and CCOB remain open after the car stop.

Cod.0: CCO open

Cod.1: CCOB open

Cod.2: CCO+CCOB open

Remedy

Check:

1- the series of auxiliary contacts (NC) of the power contactors and other cables in series on the circuit CCO and CCOB

2- the CCO and CCOB circuit wiring

3- the connection of the CCO and CCOB on the board

One or more NC contacts associated to the power contactors and connected in series on the input CCO and CCOB remain open after the car stop.

Cod.0: CCO open

Cod.1: CCOB open

Cod.2: CCO+CCOB open

Remedy

Check:

1- the series of auxiliary contacts (NC) of the power contactors and other cables in series on the circuit CCO and CCOB

2- the CCO and CCOB circuit wiring

3- the connection of the CCO and CCOB on the board

3) – Low speed too long

Description (and cause)

The lift car moves at low speed for too long. In case of VVVF may be too low engine torque in the approching floor phase.

Remedy

Check:

1- Check parameter “Low Speed fault time” (“Configuration” menu) and increase time if necessary

2- the elevator speed to a low speed (in the case of VVVF); increase it if necessary

3a- the decelerating distance to the plane indicated (magnets FAI / FAS)

3b- value of the distance R1D / R1S if Encoder is used (“System Positioning” menu)

The lift car moves at low speed for too long. In case of VVVF may be too low engine torque in the approching floor phase.

Remedy

Check:

1- Check parameter “Low Speed fault time” (“Configuration” menu) and increase time if necessary

2- the elevator speed to a low speed (in the case of VVVF); increase it if necessary

3a- the decelerating distance to the plane indicated (magnets FAI / FAS)

3b- value of the distance R1D / R1S if Encoder is used (“System Positioning” menu)

4) – Overload

Description (and cause)

Overload input (SUR) activated (NO contact).

Remedy

Check:

1- the SUR input (if locked) and wiring

2- the setting of the load weighing device

Overload input (SUR) activated (NO contact).

Remedy

Check:

1- the SUR input (if locked) and wiring

2- the setting of the load weighing device

5) – Positioning fault

Description (and cause)

This error shows a difference between the performed theoretical counting and the real position detected:

Cod.0: upon activation of the AGB/AGH limit contacts;

Cod.100: upon activation of ZP magnet floor

Cod.200: upon activation of stop level’s ZP magnet floor

Remedy

Check:

1- the correct positioning of the magnets (or flags)

2- operation of magnetic reeds or encoder; verify the arrival of 24V current

3- the distance between extreme contact and magnet

This error shows a difference between the performed theoretical counting and the real position detected:

Cod.0: upon activation of the AGB/AGH limit contacts;

Cod.100: upon activation of ZP magnet floor

Cod.200: upon activation of stop level’s ZP magnet floor

Remedy

Check:

1- the correct positioning of the magnets (or flags)

2- operation of magnetic reeds or encoder; verify the arrival of 24V current

3- the distance between extreme contact and magnet

6) – Direction fault

Description (and cause)

The controller detects the wrong direction of travel.

Remedy

Check:

1- the direction of travel of the engine (control UP vs. Car movement direction)

2- the installation and connection of FAI / FAS sensors

3- CW / CCW Encoder configuration (“System Positioning” menu)

4- AGH and AGB inputs

7) – Safety 3 open at stop

Description (and cause)

Safety chain interrupted with elevator not running. Calls are deleted. On the PlayPad Led SE3 is off.

Remedy

Check all contacts between the terminals SC2 and SE3 (Safety Gear, Limit switch, Overspeed Governor).

Safety chain interrupted with elevator not running. Calls are deleted. On the PlayPad Led SE3 is off.

Remedy

Check all contacts between the terminals SC2 and SE3 (Safety Gear, Limit switch, Overspeed Governor).

9) – Door lock fault

Description (and cause)

Safety chain open at point SE6 when a call is registered.

With automatic door: door re-opens and then closes (3 times, after which all calls are cancelled).

Other door types: after a few seconds all calls are cancelled.

Cod.5: floor locks

Cod.6: car doo

Remedy

Check all contacts between the terminals SD2 and SD3 (floor locks) or SC4 and SC5 (car doors) according code info, their connection and if an object obstructs the closing of the door to the indicated floor (POS).

In case of 81-21 devices check its contacts in Normal mode operations.

Safety chain open at point SE6 when a call is registered.

With automatic door: door re-opens and then closes (3 times, after which all calls are cancelled).

Other door types: after a few seconds all calls are cancelled.

Cod.5: floor locks

Cod.6: car doo

Remedy

Check all contacts between the terminals SD2 and SD3 (floor locks) or SC4 and SC5 (car doors) according code info, their connection and if an object obstructs the closing of the door to the indicated floor (POS).

In case of 81-21 devices check its contacts in Normal mode operations.

10) – Door A opening slippage

Description (and cause)

Only doors with limit switch: door does not open within the planned time. In case of slippage during door opening, the door is considered open.

Remedy

Check:

1- Door open limit switch (FOA) and its wiring;

2- door operator power supply and fuses;

3- door open contactors (ROA)

Only doors with limit switch: door does not open within the planned time. In case of slippage during door opening, the door is considered open.

Remedy

Check:

1- Door open limit switch (FOA) and its wiring;

2- door operator power supply and fuses;

3- door open contactors (ROA)

11) – Door B opening slippage

Description (and cause)

Same as door A, for second entrance.

Remedy

Same as A, but signals (FOB) and (ROB).

Same as door A, for second entrance.

Remedy

Same as A, but signals (FOB) and (ROB).

12) – Safety 3 open during travel

Description (and cause)

Safety chain open before Input SE3 while elevator car travelling. Car stops and elevator car calls are cancelled.

On the PlayPad Led SE3 is off.

Remedy

Check all contacts between the terminals

S35-S36 (Top of Car)

SC3-SM4 (controller)

Safety devices: Safety Gear, Limit switch, Overspeed Governor.

Safety chain open before Input SE3 while elevator car travelling. Car stops and elevator car calls are cancelled.

On the PlayPad Led SE3 is off.

Remedy

Check all contacts between the terminals

S35-S36 (Top of Car)

SC3-SM4 (controller)

Safety devices: Safety Gear, Limit switch, Overspeed Governor.

13) – Motor temperature sensor

Description (and cause)

Inputs TH1 or TH2 of motor temperature is activated (NC contact)

Cod.1: TH1 open

Cod.2: TH2 open

Cod.3: TH1 and TH2 open

Cod.10: Door’s thermic input (TOC board)

Remedy

Check inputs (TH1, TH2), sensor connections and the state of the motor’s temperature sensor.

Cod.1 Check TH1 input

Cod.2 Check TH2 input

Cod.3 Check TH1 and TH2 inputs

Cod.10 Check door’s thermic input on TOC board’s M16 Connector.

Inputs TH1 or TH2 of motor temperature is activated (NC contact)

Cod.1: TH1 open

Cod.2: TH2 open

Cod.3: TH1 and TH2 open

Cod.10: Door’s thermic input (TOC board)

Remedy

Check inputs (TH1, TH2), sensor connections and the state of the motor’s temperature sensor.

Cod.1 Check TH1 input

Cod.2 Check TH2 input

Cod.3 Check TH1 and TH2 inputs

Cod.10 Check door’s thermic input on TOC board’s M16 Connector.

14) – Parameters memory

Description (and cause)

Fault in the Eprom parameters memory.

Remedy

Reset, re-enter and record all parameters.

15) – Final limit switch

Description (and cause)

When it is reached the final limit switch (or Safety Gear or Overspeed Governor limiter trip), the input SE3 is active (NC contact).

After delay of 1,5 s the error remains in memory, even after deactivation of the signal, and inhibits the landing calls and the elevator car movements, until special reset Menu “Faults” is made (Reset SE3).

Remedy

1- Release the final limit switch (or Safety Gear or OSG) closing the safety chain (SE3) and cancel fault in the “Faults” Menu.

2- Check the connection of the NC contact between SC2 and SE3 terminals

16) – Fire detection

Description (and cause)

In case of fire sensors installed, this fault indicates that one or more sensors are active.

Remedy

Check fire sensor input(s).

In case of fire sensors installed, this fault indicates that one or more sensors are active.

Remedy

Check fire sensor input(s).

17) – Safety 4 open during travel

Description (and cause)

Safety chain open before input SE4 while elevator car travelling.

Landing calls and the elevator car movements are cancelled

On the PlayPad Led SE4 is off.

Remedy

Check all contacts between the terminals SD1 and SD2 (Preliminaries floor doors).

Safety chain open before input SE4 while elevator car travelling.

Landing calls and the elevator car movements are cancelled

On the PlayPad Led SE4 is off.

Remedy

Check all contacts between the terminals SD1 and SD2 (Preliminaries floor doors).

18) – Safety 6 open during travel

Description (and cause)

Safety chain open before Input SE6 while elevator car travelling.

landing calls and the elevator car movements are cancelled

On the PlayPad Led SE6 is off.

Cod.5: floor locks

Cod.6: elevator car door

Remedy

Check all contacts between the terminals SD2 and SD3 (floor locks).

Check all contacts between the terminals SC4 and SC5 (elevator car door).

Check all contacts between the terminals SC5 and SE6 (Protection device 81-21).

Safety chain open before Input SE6 while elevator car travelling.

landing calls and the elevator car movements are cancelled

On the PlayPad Led SE6 is off.

Cod.5: floor locks

Cod.6: elevator car door

Remedy

Check all contacts between the terminals SD2 and SD3 (floor locks).

Check all contacts between the terminals SC4 and SC5 (elevator car door).

Check all contacts between the terminals SC5 and SE6 (Protection device 81-21).

19) – Low tension during movement

Description (and cause)

Motherboard power below 17V (this fault disappears when the 24V is restored)

Cod.0: Main power Input

Cod.1: Overcurrent on VCAB

Cod.2: Overcurrent on VMR

Cod.3: Short Circuit on VCAB

Cod.4: Short Circuit on VMR

Remedy

Check the network, the supply voltage to the transformer primary, the presence of 24V and the consumption of the circuit.

Motherboard power below 17V (this fault disappears when the 24V is restored)

Cod.0: Main power Input

Cod.1: Overcurrent on VCAB

Cod.2: Overcurrent on VMR

Cod.3: Short Circuit on VCAB

Cod.4: Short Circuit on VMR

Remedy

Check the network, the supply voltage to the transformer primary, the presence of 24V and the consumption of the circuit.

20) – Travel interrupted

Description (and cause)

During upward (or downward) movements contactors open while RMO (or RDE) commands are active. Possible short interruption of the safety circuit while moving.

Cod.100: CCO signal falling during travel

Cod.200: CCOB signal falling during tavel

Remedy

Check:

1- Preliminary contacts and door lockers at the indicated floor

2- car door contacts

3- the supply voltage of the safety circuit

During upward (or downward) movements contactors open while RMO (or RDE) commands are active. Possible short interruption of the safety circuit while moving.

Cod.100: CCO signal falling during travel

Cod.200: CCOB signal falling during tavel

Remedy

Check:

1- Preliminary contacts and door lockers at the indicated floor

2- car door contacts

3- the supply voltage of the safety circuit

21) – CCO input blocked

Description (and cause)

The contactors control circuit (Input CCO) remains closed after travel command is given

Cod.100: CCO

Cod.200: CCOB

Cod.250: CTB not activated

Remedy

Check:

1- wiring and state of the auxiliary contacts (NC) of the power contactors and other NC contacts wired in series on the CCO / CCOB circuit

2- CCO / CCOB Motherboard input

22) – Low tension at stop

Description (and cause)

Same as Fault N.19

Cod.0: Main power Input

Cod.1: Overcurrent on VCAB

Cod.2: Overcurrent on VMR

Cod.3: Short Circuit on VCAB

Cod.4: Short Circuit on VMR

Remedy

Check the network, the supply voltage to the transformer primary, the presence of 24V and the consumption of the circuit.

Same as Fault N.19

Cod.0: Main power Input

Cod.1: Overcurrent on VCAB

Cod.2: Overcurrent on VMR

Cod.3: Short Circuit on VCAB

Cod.4: Short Circuit on VMR

Remedy

Check the network, the supply voltage to the transformer primary, the presence of 24V and the consumption of the circuit.

23) – AGB blocked

Description (and cause)

The expected operation of AGB (NC) contact is not checked.

Cod.100: contact is not closed at floor different from bottom floor (downward calls erased).

Cod.200: contact is not open at lowest floor (lift locked)

Remedy

Check the condition of the contact AGB (mechanical switch or magnetic sensor) and the AGB circuit wiring.

The expected operation of AGB (NC) contact is not checked.

Cod.100: contact is not closed at floor different from bottom floor (downward calls erased).

Cod.200: contact is not open at lowest floor (lift locked)

Remedy

Check the condition of the contact AGB (mechanical switch or magnetic sensor) and the AGB circuit wiring.

24) – AGH blocked

Description (and cause)

The expected operation of AGH (NC) contact is not checked.

Cod.100: contact is not closed at floor different from top floor (upward calls erased).

Cod.200: contact is not open at top floor (lift locked)

Remedy

As for the error 23, regarding the AGH input.

The expected operation of AGH (NC) contact is not checked.

Cod.100: contact is not closed at floor different from top floor (upward calls erased).

Cod.200: contact is not open at top floor (lift locked)

Remedy

As for the error 23, regarding the AGH input.

25) – AGH and AGB simultaneously

Description (and cause)

Inputs AGB / AGH opened simultaneously. The system shuts down.

Remedy

Check the condition of AGH and AGB contacts (mechanical or magnetic) and their wiring.

When one of the two contacts is closed, the system performs a reset manoeuvre.

Inputs AGB / AGH opened simultaneously. The system shuts down.

Remedy

Check the condition of AGH and AGB contacts (mechanical or magnetic) and their wiring.

When one of the two contacts is closed, the system performs a reset manoeuvre.

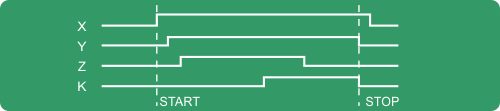

26) – Running time UP

Description (and cause)

No change in the beam status for motion sensors (or floor) for more than planned during car travel. In case of encodeur the threshold is 1 sec. over AGB/AGH limit point

Cod.0: problem on FAI FAS input (no changing of inputs for time longer than “Running time” parameter

Cod.100: problem on encoder channel

Cod.200: no changing of ZP input for time longer than “Running time” parameter.

Remedy

Check contactors, brake, motor power supply, FAI/FAS sensors (or ENCODER).

Check “X1” and “12” inputs of the VVVF. Anti-slippage test (See insights “Test and measurements”).

27) – Running time DOWN

Description (and cause)

See above but in downward movement.

Remedy

See above but in downward movement.

28) – Door A closing slippage

Description (and cause)

Only doors with limit switch:

Door A does not close within programmed time.

3 complete opening/closing cycles are performed, then all registered calls are cancelled.

Remedy

Check:

1- door close limit switch FFA (NC contact) and wiring

2- door motor power supply and fuses

3- door close contactors (RFA)

Only doors with limit switch:

Door A does not close within programmed time.

3 complete opening/closing cycles are performed, then all registered calls are cancelled.

Remedy

Check:

1- door close limit switch FFA (NC contact) and wiring

2- door motor power supply and fuses

3- door close contactors (RFA)

29) – Door B closing slippage

Description (and cause)

Same as door A, for second entrance.

Remedy

Same as door A, but signals (FFB) and (RFB).

Same as door A, for second entrance.

Remedy

Same as door A, but signals (FFB) and (RFB).

30) – Out of service switch

Description (and cause)

If the relevant parameter has been programmed, it indicates that the system has been put out of service through the activation of input HS.

Cod.0: Key HS activation

Cod.100: BDU’s key activation.

Cod.200: cabine key activation.

Remedy

Check input out of service input (NO contact).

Cod.0: input HS on screw temrinal

Cod.100: inut IN 2 on BDU

Cod.200: input SPARE on DMCPIT

If the relevant parameter has been programmed, it indicates that the system has been put out of service through the activation of input HS.

Cod.0: Key HS activation

Cod.100: BDU’s key activation.

Cod.200: cabine key activation.

Remedy

Check input out of service input (NO contact).

Cod.0: input HS on screw temrinal

Cod.100: inut IN 2 on BDU

Cod.200: input SPARE on DMCPIT

31) – FAI/FAS error

Description (and cause)

Simultaneous variation of FAI/FAS positioning sensors. POS [n] indicates that the error occurred at floor [n].

POS 100 indicates a wrong sequence of beams.

Remedy

Check power supply to sensors;

Check sensors and magnets position.

Simultaneous variation of FAI/FAS positioning sensors. POS [n] indicates that the error occurred at floor [n].

POS 100 indicates a wrong sequence of beams.

Remedy

Check power supply to sensors;

Check sensors and magnets position.

32) – Temporary operation without inspection

Description (and cause)

During temporary operations the input REV or REV1 or REV2 must be active or the lift will not move.

Remedy

Check input REV, REV1 or REV2 (NC contact).

During temporary operations the input REV or REV1 or REV2 must be active or the lift will not move.

Remedy

Check input REV, REV1 or REV2 (NC contact).

33) – Stopping accuracy

Description (and cause)

When the lift stops at floor, the two FAI/FAS LEDs are on. If within 2 seconds from the stop one of the beams is interrupted, this fault occurs. If the system is equipped with ENCODER the uncertainty of the stop is more than 2 cm.

Remedy

Check:

1- position of the magnets;

2- deceleration distances;

3- motor brake

When the lift stops at floor, the two FAI/FAS LEDs are on. If within 2 seconds from the stop one of the beams is interrupted, this fault occurs. If the system is equipped with ENCODER the uncertainty of the stop is more than 2 cm.

Remedy

Check:

1- position of the magnets;

2- deceleration distances;

3- motor brake

34) – Anti-nuisance

Description (and cause)

It appears after a call cancellation and if the parameter “Anti-nuisance” has been programmed.

The reason is too many calls from the elevator car without the cell being cut (in case of combined doors) or without landing doors opening (other door types).

Remedy

Change number of unwanted calls in the Anti-nuisance parameter.

It appears after a call cancellation and if the parameter “Anti-nuisance” has been programmed.

The reason is too many calls from the elevator car without the cell being cut (in case of combined doors) or without landing doors opening (other door types).

Remedy

Change number of unwanted calls in the Anti-nuisance parameter.

35) – Lift not avalaible

Description (and cause)

The lift cannot take calls and is not considered for call dispatching (in multiplex). After 3 closing door cycles, the lift is considered unavailable for 1 minute.

Cod.10: No power on car light

Only in multiplex:

Cod.100: light curtain / door open button

Cod.200: no SE4 signal (eg manual door not closed)

The lift cannot take calls and is not considered for call dispatching (in multiplex). After 3 closing door cycles, the lift is considered unavailable for 1 minute.

Cod.10: No power on car light

Only in multiplex:

Cod.100: light curtain / door open button

Cod.200: no SE4 signal (eg manual door not closed)

36) – Phase sequence

Description (and cause)

Wrong sequence in input phases. Could be detected even during system shutdown.

Remedy

Check the right sequence of phases or swap two phases on power input terminals L1-L2-L3.

Wrong sequence in input phases. Could be detected even during system shutdown.

Remedy

Check the right sequence of phases or swap two phases on power input terminals L1-L2-L3.

37) – Low battery

Description (and cause)

Low charge on 24V battery.

Remedy

Test battery charge or change battery.

Low charge on 24V battery.

Remedy

Test battery charge or change battery.

38) – SE2 open

Description (and cause)

Safety chain open. Landing calls and the car movements are cancelled. Playpad SE2 led is off.

Cod.0: DIS switch open (SE0 led off)

Cod.1: PIT safety circuit open (SE1 led off)

Cod.2: TOC safety circuit open (SE2 led off).

Remedy

Check DIS Switch

Check all contacts between the terminals SP3 and SP4 (STOP in the pit, pit ladder, Inspection box, etc.).

Check all contacts between the terminals SC1 and SC2 (STOP on the Toc, Toc protection, Inspection box, etc).

Safety chain open. Landing calls and the car movements are cancelled. Playpad SE2 led is off.

Cod.0: DIS switch open (SE0 led off)

Cod.1: PIT safety circuit open (SE1 led off)

Cod.2: TOC safety circuit open (SE2 led off).

Remedy

Check DIS Switch

Check all contacts between the terminals SP3 and SP4 (STOP in the pit, pit ladder, Inspection box, etc.).

Check all contacts between the terminals SC1 and SC2 (STOP on the Toc, Toc protection, Inspection box, etc).

39) – Ambient temperature

Description (and cause)

This error indicates that the ambient temperature detected by the sensor is outside the set limits.

Cod.100: Temperature below the lower threshold;

Cod.200: temperatures above the higher threshold.

Remedy

1 – Check the presence and connection of the temperature sensor.

2 – Control activation, the threshold adjustment and sensor calibration can be made in the “Special Features menu”.

This error indicates that the ambient temperature detected by the sensor is outside the set limits.

Cod.100: Temperature below the lower threshold;

Cod.200: temperatures above the higher threshold.

Remedy

1 – Check the presence and connection of the temperature sensor.

2 – Control activation, the threshold adjustment and sensor calibration can be made in the “Special Features menu”.

40) – Fault RSP

Description (and cause)

For reduced pit and headroom.

Cod.20: pit access according EN81.20

Cod.21: shaft access according EN81.21

Cod.41: Fake pit access according EN81.41

Cod.111: Monitor Relay RSDC fail (contact doesn’t open)

Cod.121: reset circuit bi stable contact EN81.21 (automatic reset)

Cod.131: Bistabile circuit (relay RSR1)

Cod.132: Bistabile circuit (relay RSR2)

Remedy

Clear RSP parameter in the menu “Faults”.

Cod.41 (Junior): the fault reset itself automatically after restoring the fake pit circuit (input E511 closed)

Cod.111 check right working of relay RSDC

Cod.121: check reset circuit. It could be possible automatic reset of bi stable contacts caused by problem on reset circuit. The contact series must be open and then make a standard reset.

Cod.131 (132) check right working of relsy RSR1 (RSR2) and after make the Reset procedure.

41) – Fault ISO

Description (and cause)

Problem detected in the operation monitoring of safety module for advanced door opening / re-leveling. If activated, the installation goes into “out of service” mode at the top floor (electric) or bottom floor (hydro).

Cod.10: Monitor Relay RISO fail

Cod.100: fail on Safety module monitor during travel

Cod.200: fail on Safety module monitor at level

Remedy

Check the alignment of ISO1 and ISO2.

Reset ISO in the menu “Faults”.

42) – TOC Communication

Description (and cause)

No serial link between controller and elevator car (in case of elevator car serial link system configuration).

Remedy

Check CAN link between controller and top of elevator car board.

No serial link between controller and elevator car (in case of elevator car serial link system configuration).

Remedy

Check CAN link between controller and top of elevator car board.

43) – Inspection

Description (and cause)

The system is in Inspection mode (NORM/ISP switch set to Inspection).

EN 81.1/2

Cod.1: REV input open (STD Version)

Cod.2: TOC’s REV1 input open

Cod.3: REV + TOC’s REV1 input open

Cod.5: REV input open (Pitagora version)

Cod.6: REV1 input open

Cod.7: REV + TOC’s REV1 input open

EN 81.20

Cod.11: PME inspection (REV)

Cod.12: TOC inspection (REV1)

Cod.13: PME + TOC inspection (REV + REV1)

Cod.14: PIT Inspection (REV2)

Cod.15: PME + PIT Inspection (REV + REV2)

Cod.16: TOC + PIT Inspection (REV1 + REV2)

Cod.17: PME + TOC + PIT Inspection (REV + REV1 + REV2)

Remedy

To exit the inspection mode move the NORM/ISP switch to Normal and close the safety chain to trigger the reset procedure.

The system is in Inspection mode (NORM/ISP switch set to Inspection).

EN 81.1/2

Cod.1: REV input open (STD Version)

Cod.2: TOC’s REV1 input open

Cod.3: REV + TOC’s REV1 input open

Cod.5: REV input open (Pitagora version)

Cod.6: REV1 input open

Cod.7: REV + TOC’s REV1 input open

EN 81.20

Cod.11: PME inspection (REV)

Cod.12: TOC inspection (REV1)

Cod.13: PME + TOC inspection (REV + REV1)

Cod.14: PIT Inspection (REV2)

Cod.15: PME + PIT Inspection (REV + REV2)

Cod.16: TOC + PIT Inspection (REV1 + REV2)

Cod.17: PME + TOC + PIT Inspection (REV + REV1 + REV2)

Remedy

To exit the inspection mode move the NORM/ISP switch to Normal and close the safety chain to trigger the reset procedure.

44) – Re-levelling not completed

Description (and cause)

Hydraulic lifts: the re-levelling procedure was not completed within 10 seconds. All subsequent re-levelling requests at the same floor are inhibited.

Remedy

Check:

1- the correct operation of the Safety module and of its sensors ZP1 and ZP2;

2- Check the FAI/FAS or ENCODER sensors and the ZP sensor;

3- position of the magnets in the re-levelling zone;

4- RISO relay.

Hydraulic lifts: the re-levelling procedure was not completed within 10 seconds. All subsequent re-levelling requests at the same floor are inhibited.

Remedy

Check:

1- the correct operation of the Safety module and of its sensors ZP1 and ZP2;

2- Check the FAI/FAS or ENCODER sensors and the ZP sensor;

3- position of the magnets in the re-levelling zone;

4- RISO relay.

45) – Fault ZP

Description (and cause)

Door zone contact stays open when the sensor is in door zone position.

Remedy

Check the correct operation of the door zone sensor (if present);

See Fault # 33.

Door zone contact stays open when the sensor is in door zone position.

Remedy

Check the correct operation of the door zone sensor (if present);

See Fault # 33.

46) – Multiplex link interrupted

Description (and cause)

In multiplex systems, this fault indicates that the link between two or more controllers in the multiplex loop is missing. Every controller switch to SIMPLEX-like functioning.

Cod.0: cable wiring between controller

Cod.255: firmware problem

Remedy

Check the connection between the controllers (MULX board);

Check all multiplex settings.

In multiplex systems, this fault indicates that the link between two or more controllers in the multiplex loop is missing. Every controller switch to SIMPLEX-like functioning.

Cod.0: cable wiring between controller

Cod.255: firmware problem

Remedy

Check the connection between the controllers (MULX board);

Check all multiplex settings.

47) – Faults memory

Description (and cause)

Errors in the faults memory.

Remedy

Erase all faults

Errors in the faults memory.

Remedy

Erase all faults

48) – BDU link unavailable

Description (and cause)

In case of serial communication with floors, indicates the loss of link between the controller and all BDU modules at floors.

On BDUs

Green LED fast blinking (0,5 sec): OK

Green LED slow blinking (1 sec): OK BDU is not addressed

Red LED ON: BDU defective

Red LED slow blinking (1 sec): communication not established.

Red + Green LED slow blinking (1 sec): sync.

Remedy

Check:

1- BDU connector on screw terminals;

2- connection between the controller and the closest BDU;

3- the system configuration (“Configuration” menu)

In case of serial communication with floors, indicates the loss of link between the controller and all BDU modules at floors.

On BDUs

Green LED fast blinking (0,5 sec): OK

Green LED slow blinking (1 sec): OK BDU is not addressed

Red LED ON: BDU defective

Red LED slow blinking (1 sec): communication not established.

Red + Green LED slow blinking (1 sec): sync.

Remedy

Check:

1- BDU connector on screw terminals;

2- connection between the controller and the closest BDU;

3- the system configuration (“Configuration” menu)

49) – BDU fault

Description (and cause)

In case of serial communication with floors, indicates the loss of link between the controller and one or more BDU at floors.

On the BDU GREEN LED fast blinking (0,5 sec): OK

GREEN LED slow blinking (1 sec): OK BDU not addressed

RED LED ON: Faulty BDU

RED LED slow blinking (1 sec): no communication.

GREEN and RED LEDs slow blinking (1 sec): communication sync in progress.

Remedy

Check BDU functions and its connections;

Change defective BDUs;

Repeat addressing procedure.

In case of serial communication with floors, indicates the loss of link between the controller and one or more BDU at floors.

On the BDU GREEN LED fast blinking (0,5 sec): OK

GREEN LED slow blinking (1 sec): OK BDU not addressed

RED LED ON: Faulty BDU

RED LED slow blinking (1 sec): no communication.

GREEN and RED LEDs slow blinking (1 sec): communication sync in progress.

Remedy

Check BDU functions and its connections;

Change defective BDUs;

Repeat addressing procedure.

50) – Drift control

Description (and cause)

Drift control (if provided) activation: the system is put out of service at an extreme floor.

Remedy

Reset 82212 in the menu “Faults”.

Drift control (if provided) activation: the system is put out of service at an extreme floor.

Remedy

Reset 82212 in the menu “Faults”.

51) – Wrong Password

Description (and cause)

If the system has a password, this fault appears after entering the wrong password for three times.

Remedy

–

If the system has a password, this fault appears after entering the wrong password for three times.

Remedy

–

52) – Fault VVVF

Description (and cause)

A fault occurred in the inverter

Code value is the subcode info of VVVF’s fault.

Remedy

Only in case of VVVF FUJI FRENIC LIFT.

See the tables “VVVF Fault table” and “VVVF alarm subcode table” in the section VVVF Frenic Lift Setting.

A fault occurred in the inverter

Code value is the subcode info of VVVF’s fault.

Remedy

Only in case of VVVF FUJI FRENIC LIFT.

See the tables “VVVF Fault table” and “VVVF alarm subcode table” in the section VVVF Frenic Lift Setting.

53) – Fault UCM

Description (and cause)

UCM Circuit Fault:

Cod.1: 81.20 lift with open door maneuvers without UCM solution

Cod.2: Brakes open

Cod.3: Brakes closed in travel

Cod.4: Monitor error GMV NGV A3

RDY = RUN = OFF

Cod.5: Monitor error GMV NGV A3

RDY = RUN = ON

Cod.6: error Test two valves

Cod.8: error Test two valves (START ELEVATOR)

Cod.10: Monitor SMA i-Valve fail (SMA not at 0V)

Cod.11: Monitor SMA i-Valve fail (SMA not at 24V)

Cod.12: Monitor Y2 lift in travel

Cod.13: Monitor Y2 lift standstill

Cod.14: Monitor Y3 lift in travel

Cod.15: Monitor Y3 lift standstill

Cod.100: UCM Detection

Cod.200: Monitor error on RUCM1/RUCM2

Cod.201: RUCM1 Stucked Open

Cod.202: RUCM2 Stucked Open

Cod.203: RUCM3 Stucked Open

Cod.204: Monitor OSG A3 (stud stucked in extended position)

Cod.210: RUCM1 Stucked Close

Cod.220: RUCM2 Stucked Close

Cod.230: RUCM3 Stucked Close

Cod.240: Monitor OSG A3 (stud stucked in retracted position)

Remedy

Reset UCM in the menu “Faults”.

Cod.1: exclude maneuvers with open doors (re-leveling / early opening).

Cod.12/13: check wiring and valve Y2 and its monitor signal

Cod.14/15: check wiring and valve Y3 and its monitor signal

Cod.100: means Unintended Cabine Movement (UCM) detection. If it happens togheter with Fault 41 (Fault ISO) check the sensors ZP1 and ZP2.

54) – Safety zone

Description (and cause)

Only for lift with no elevator car door and safety light curtains.

Cod.0: Light curtain active during travel (lift wait for a new Car call to restart)

Cod.1: Fail test CEDES door side A

Cod.2: Fail test CEDES door side B

Cod.10: Fail test on safety relay KSA

Cod.20: Fail test on safety relay KSB

Remedy

Check circuit according cod’s info..

Only for lift with no elevator car door and safety light curtains.

Cod.0: Light curtain active during travel (lift wait for a new Car call to restart)

Cod.1: Fail test CEDES door side A

Cod.2: Fail test CEDES door side B

Cod.10: Fail test on safety relay KSA

Cod.20: Fail test on safety relay KSB

Remedy

Check circuit according cod’s info..

55) – Fault SCS

Description (and cause)

Safety Circuit Shunt.

Function enabled by “Shaft Monitor” parameter. See Shaft protection.

Cod.2: Second contact door A shunted (FFA Signal).

Cod.4: Floor door contacts door A Shunted (SE4 input)

Cod.6: Car door contacts door A Shunted (SE6 input)

Cod.12: Second contact door B shunted (FFA Signal).

Cod.14: Floor door contacts door B Shunted (SE4 input)

Cod.16: Car door contacts door B Shunted (SE6 input)

Cod.100: No SE6 input during bypass (ISO Circuit)

Remedy

Check circuit according cod’s info.

Reset SCS parameter in the menu “Faults”.

Cod.2: Check second contact door A (FFA input for door operator, CEA input for manual cabine door).

Cod.4: Check Floor door’s safety contacts door A (SE4 input)

Cod.6: Check Car door’s safety contacts door A (SE6 input)

Cod.12: Check second contact door B (FFB input for door operator, CEB input for manual cabine door).

Cod.14: Check Floor door’s safety contacts door B (SE4 input)

Cod.16: Check Car door’s safety contacts door B (SE6 input)

Cod.100: Check doors bypass Circuit (SE3-SC5).

56) – Fault UAS

Description (and cause)

Unintended Shaft Access

Function enabled by “Shaft Monitor” parameter.

Must be used BDU with additional door input (could be NO or NC).

System detect a manually floor door opening monitoring the auxiliary door input.

Cod.1: One Floor door manually open (with no open door command).

Cod.2: More than one Floor door manually open (at different floors)

Remedy

Reset UAS in the menu “Faults”.

57) – Bypass door

Description (and cause)

Only for EN 81-20.

Bypass active on door safety contacts.

(Moving enabled only in inspection)

Check also SM1 module monitor

Cod.1: Bypass Car active

Cod.2: Bypass Pre-Locks active

Cod.3: Bypass Locks active

Cod.100: Module SM1 locked

Remedy

Cod.100: Module SM1 is checked if only PME selector is active and no STOPS nor direction button pressed: in that condition module SM1 must be not enabled and SE3 input should be open.

Only for EN 81-20.

Bypass active on door safety contacts.

(Moving enabled only in inspection)

Check also SM1 module monitor

Cod.1: Bypass Car active

Cod.2: Bypass Pre-Locks active

Cod.3: Bypass Locks active

Cod.100: Module SM1 locked

Remedy

Cod.100: Module SM1 is checked if only PME selector is active and no STOPS nor direction button pressed: in that condition module SM1 must be not enabled and SE3 input should be open.

58) – Overspeed

Description (and cause)

Only for Encoder positioning system.

In inspection or Temporary mode Lift’s speed is more than 0,63 m/s

Remedy

Check encoder parameters or inspection speed in “System Positioning” menu.

Only for Encoder positioning system.

In inspection or Temporary mode Lift’s speed is more than 0,63 m/s

Remedy

Check encoder parameters or inspection speed in “System Positioning” menu.

59) – Fault SHI

Description (and cause)

Only for 81-21 Pre-triggered device.

Cod.0: Wrong feedback when pre-triggered device is not energized

Cod.255: Wrong feedback when pre-triggered device is energized

Manual protection:

Cod.101: Monitor Relay RMPP (contact doesn’t open)

Cod.102: Monitor Relay RMPP (contact doesn’t close)

Remedy

Check Pre-Triggered Device (or relay RMPP)

Only for 81-21 Pre-triggered device.

Cod.0: Wrong feedback when pre-triggered device is not energized

Cod.255: Wrong feedback when pre-triggered device is energized

Manual protection:

Cod.101: Monitor Relay RMPP (contact doesn’t open)

Cod.102: Monitor Relay RMPP (contact doesn’t close)

Remedy

Check Pre-Triggered Device (or relay RMPP)

60) – Fault ELGO

Description (and cause)

ELGO Fault.

Cod.0: Upper Limit switch

Cod.1: Lower Limit switch

Cod.4: Pre-triggered Stopping system Top

Cod.5: Pre-triggered Stopping system Bottom

Cod.8: Normal mode overspeed (pre tripping)

Cod.9: Normal mode overspeed (final tripping)

Cod.11: Inspection mode overspeed (final tripping)

Cod.13: Teach mode overspeed (final tripping)

Cod.14: Normal mode overspeed (leveling)

Cod.15: Normal mode overspeed (re-leveling)

Cod.16: Deceleration control (ETSL)

Cod.24: Unintended elevator car movement

Cod.100: ELGO not in operative mode

Cod.102: ELGO’s Input EN81-21 in Manual Teach mode

Cod.103: ELGO’s eSGC_POW missing in Manual Teach mode

Cod.104: Restarting error during manual learning procedure

Cod.121: Input ELGO 81.21 not matching (all time OFF)

Cod.122: Inputs ELGO UP/DOWN (not active)

Cod.123: Input ELGO UP not matching

Cod.124: Input ELGO DOWN not matching

Cod.125: Inputs ELGO UP/DOWN not matching (all time ON)

Cod.200: Communication time out

Cod.254: Self test ELGO Error Level 4

Cod.255: Magnetic Band missing

Remedy

Check ELGO configuration data.

Check ELGO wiring.

Make a Fault reset to remove the fault.

Cod.0: Move car down (under the limit switch position) and make a specific Reset SE3 fault (§5.3).

Cod.1: Move car up (over the limit switch position) and make a specific Reset SE3 fault (§5.3).

Cod.4: only information, Inspection upper limit switch.

Cod.5: only information, Inspection lower limit switch.

Cod.8/9: Make a Fault reset. Check Lift speed and ELGO’s Configuration.

Cod.11: Make a Fault reset. Check Lift speed and ELGO’s Configuration.

Cod.13: Make a Fault reset. Reduce the lift speed in Teach mode (max 0,6 m/s).

Cod.14: Make a Fault reset. Reduce the lift speed during the stop at floor (max 0,8 m/s).

Cod.15: Make a Fault reset. Reduce the lift speed in re-levelling (max 0,3 m/s).

Cod.16: Fault is automatically removed when lift is standstill. Increase Deceleration distances (R1D/R1S).

Cod.20: In Inspection, on the lower limit switch a down movement checked with a UP command. Check rollback effect.

Cod.21: In Inspection, on the higer limit switch an up movement checked with a DOWN command. Check rollback effect.

Cod.100: Need a Manual Teach procedure

Cod.102: Check wiring of ZP2 signal in the controller

Cod.103: Check wiring of cable eSGC (power missing)

Cod.104: The device needs a replacement

Cod.121: Check wiring of ELGO and TOC’s signal output. Error means a mismatch between command from controller and ELGO’s diagnostic.

Cod. from 121 to 125: Check wiring of ELGO and TOC’s signals output. Errors means a mismatch between commands from controller and ELGO’s diagnostic.

Cod.200: Check wiring TOC- ELGO (Can signals)

Cod.254: Noise on eSGC signal’s cable. Put a relay on TOC box to open the load line when eSGC output is not active.

Cod.255: Check mounting of the magnetic band and mountingdirection as well.

ELGO Fault.

Cod.0: Upper Limit switch

Cod.1: Lower Limit switch

Cod.4: Pre-triggered Stopping system Top

Cod.5: Pre-triggered Stopping system Bottom

Cod.8: Normal mode overspeed (pre tripping)

Cod.9: Normal mode overspeed (final tripping)

Cod.11: Inspection mode overspeed (final tripping)

Cod.13: Teach mode overspeed (final tripping)

Cod.14: Normal mode overspeed (leveling)

Cod.15: Normal mode overspeed (re-leveling)

Cod.16: Deceleration control (ETSL)

Cod.24: Unintended elevator car movement

Cod.100: ELGO not in operative mode

Cod.102: ELGO’s Input EN81-21 in Manual Teach mode

Cod.103: ELGO’s eSGC_POW missing in Manual Teach mode

Cod.104: Restarting error during manual learning procedure

Cod.121: Input ELGO 81.21 not matching (all time OFF)

Cod.122: Inputs ELGO UP/DOWN (not active)

Cod.123: Input ELGO UP not matching

Cod.124: Input ELGO DOWN not matching

Cod.125: Inputs ELGO UP/DOWN not matching (all time ON)

Cod.200: Communication time out

Cod.254: Self test ELGO Error Level 4

Cod.255: Magnetic Band missing

Remedy

Check ELGO configuration data.

Check ELGO wiring.

Make a Fault reset to remove the fault.

Cod.0: Move car down (under the limit switch position) and make a specific Reset SE3 fault (§5.3).

Cod.1: Move car up (over the limit switch position) and make a specific Reset SE3 fault (§5.3).

Cod.4: only information, Inspection upper limit switch.

Cod.5: only information, Inspection lower limit switch.

Cod.8/9: Make a Fault reset. Check Lift speed and ELGO’s Configuration.

Cod.11: Make a Fault reset. Check Lift speed and ELGO’s Configuration.

Cod.13: Make a Fault reset. Reduce the lift speed in Teach mode (max 0,6 m/s).

Cod.14: Make a Fault reset. Reduce the lift speed during the stop at floor (max 0,8 m/s).

Cod.15: Make a Fault reset. Reduce the lift speed in re-levelling (max 0,3 m/s).

Cod.16: Fault is automatically removed when lift is standstill. Increase Deceleration distances (R1D/R1S).

Cod.20: In Inspection, on the lower limit switch a down movement checked with a UP command. Check rollback effect.

Cod.21: In Inspection, on the higer limit switch an up movement checked with a DOWN command. Check rollback effect.

Cod.100: Need a Manual Teach procedure

Cod.102: Check wiring of ZP2 signal in the controller

Cod.103: Check wiring of cable eSGC (power missing)

Cod.104: The device needs a replacement

Cod.121: Check wiring of ELGO and TOC’s signal output. Error means a mismatch between command from controller and ELGO’s diagnostic.

Cod. from 121 to 125: Check wiring of ELGO and TOC’s signals output. Errors means a mismatch between commands from controller and ELGO’s diagnostic.

Cod.200: Check wiring TOC- ELGO (Can signals)

Cod.254: Noise on eSGC signal’s cable. Put a relay on TOC box to open the load line when eSGC output is not active.

Cod.255: Check mounting of the magnetic band and mountingdirection as well.