(v 1.0)

Safety and usage cautions

Before installing our products, we recommend you to consult the section about safety and usage cautions at the link below

Introduction

PROPHESIX is DMG’s monitoring device designed for the remote supervision of any elevator, fully independent of the controller.

Installed on the top of car, PROPHESIX features sensors for detecting car movement and position, along with configurable inputs and outputs enabling precise system control.

System components

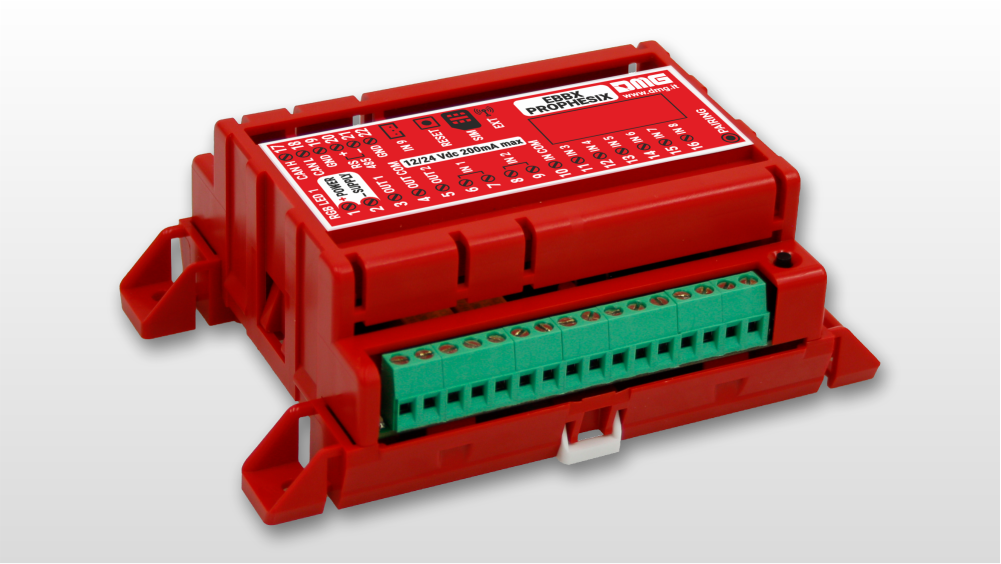

Electronic control unit

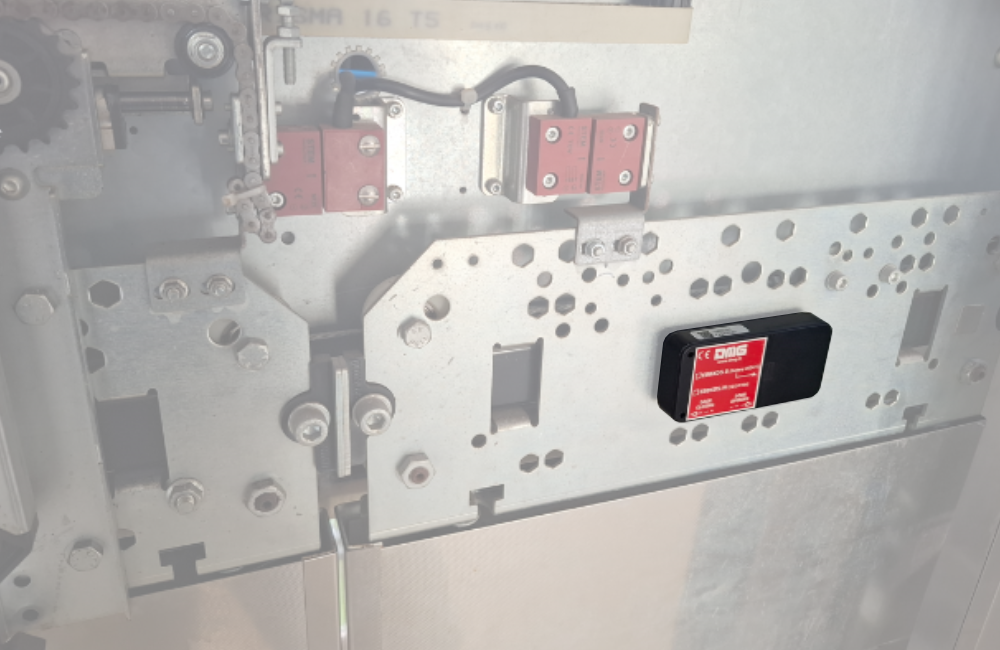

It is an advanced device installed on the elevator car roof, designed to continuously monitor elevator movements and position through integrated sensing technology.

The device provides two outputs for simulating car calls to the top and bottom floors or other remote commands, along with 8 inputs for optional sensors, enabling detailed and reliable monitoring of the elevator status (floor detection, door operation, out-of-service, maintenance, etc.).

Integrated 4G connectivity ensures real-time communication with a remote server, while WiFi and BLE interfaces allow connection to external sensors and to an optional external modem, ensuring service continuity even in environments with limited signal coverage inside the elevator shaft.

The device can be easily configured via smartphone and cloud platform, offering maximum flexibility and ease of installation.

Supplied with an included 1 GB data SIM, it guarantees connectivity for up to 5 years, reducing operating costs and maintenance requirements.

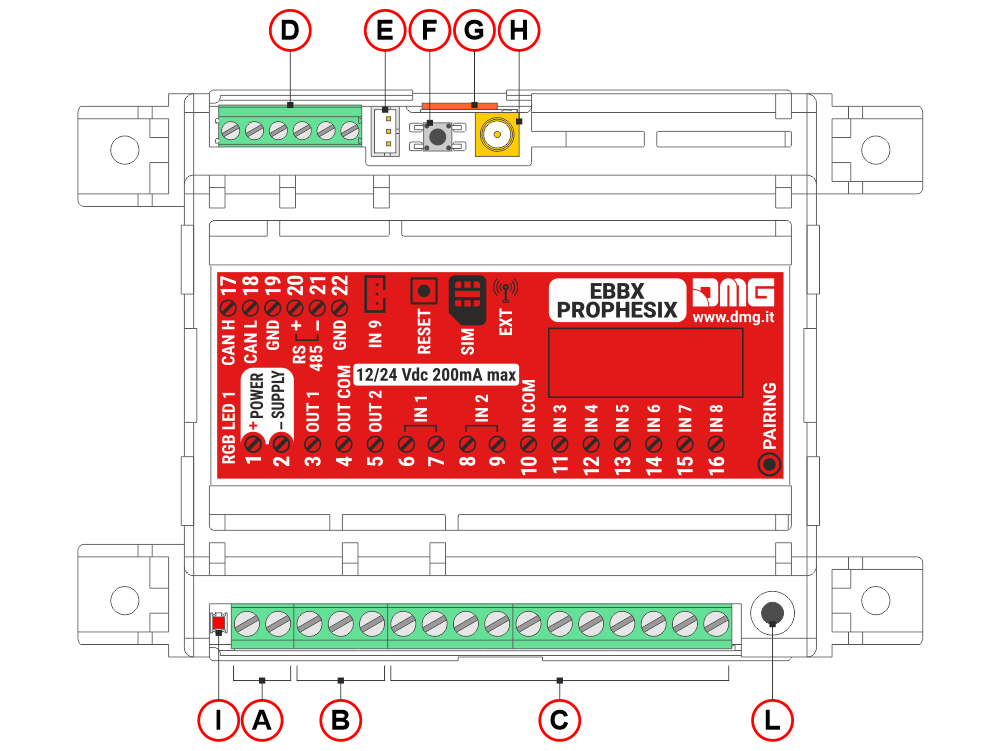

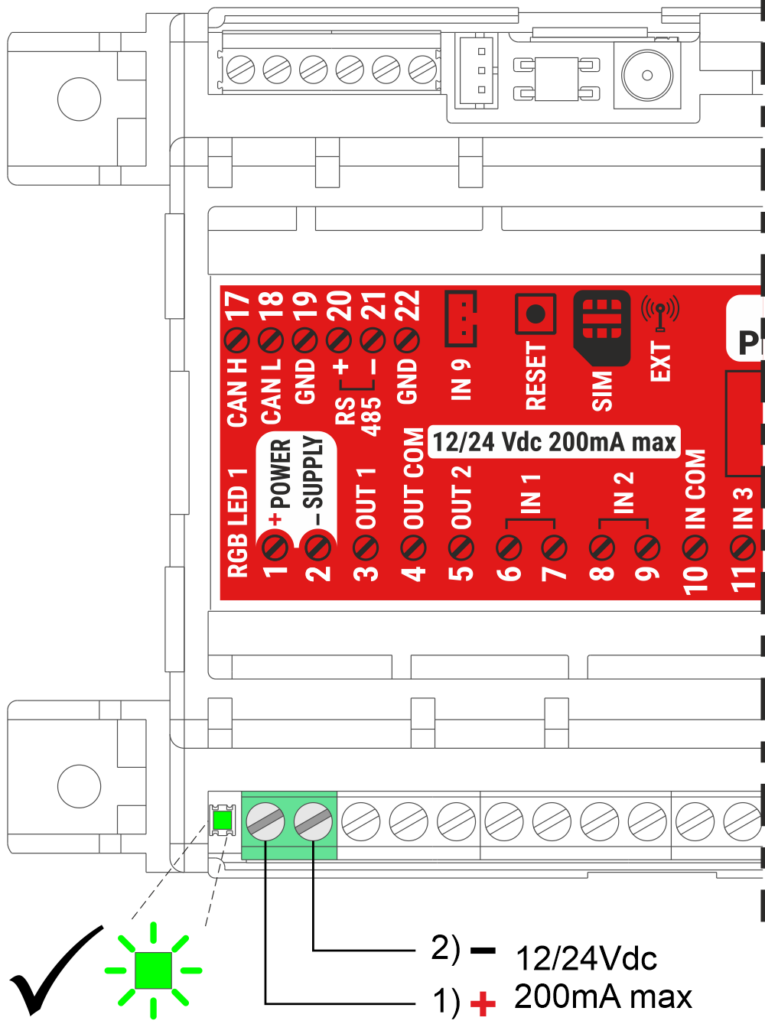

A) Power supply input (12/24Vdc 200mA max)

B) Two outputs for simulating car calls to the top and bottom floors or other remote commands

C) 8 opto-isolated, configurable inputs for optional sensors, enabling more accurate monitoring of the lift status (floor detection, door operation, out-of-service, maintenance, etc.).

D) Inputs for RS485 or CAN serial communication with other device (display, controllers, etc.

E) Light sensor

F) Reset SW button

G) micro-SIM card for 4G connection

H) input for 4G mobile antenna

I) Diagnostic LED

L) User button

Door sensor

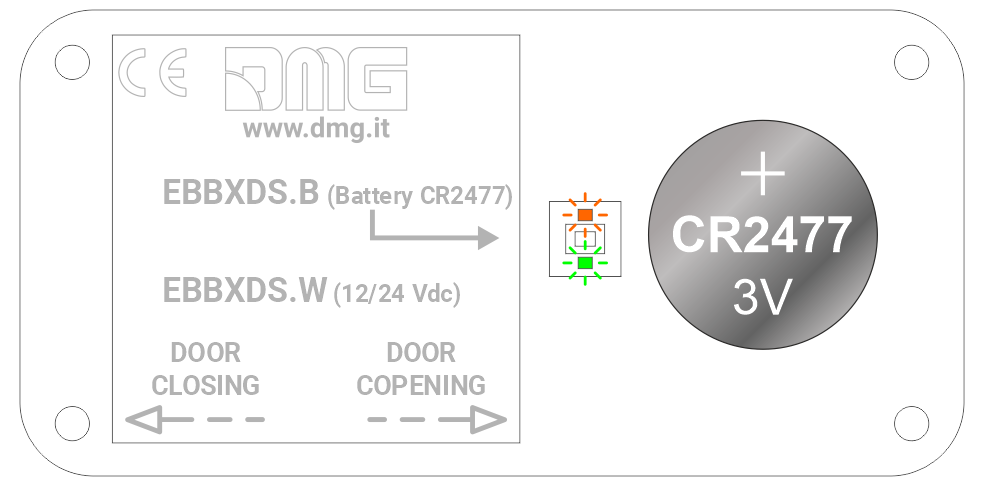

Optional device installed on the car doors for monitoring door movement.

The device is equipped with an internal battery and BTLE connectivity for wireless communication with the control unit.

FUSION app / dashboard

The DMG FUSION cloud platform collects and processes data transmitted by the Prophesix device.

Through FUSION, it is possible to:

• Configure the Prophesix system.

• Remotely monitor the elevator system status.

• Analyze data and statistics related to elevator usage and operating conditions over time.

The main available information includes:

• Elevator status logging (e.g. Normal operation, Inspection mode, Out of service)

• Car and door movement logging (up/down trips, operating time, distance traveled)

• Anomaly logging (e.g. interrupted travel, sudden accelerations/decelerations, door malfunctions)

• Scheduling of test calls to verify the actual operating condition of the elevator

Associazione del dispositivo alla piattaforma FUSION

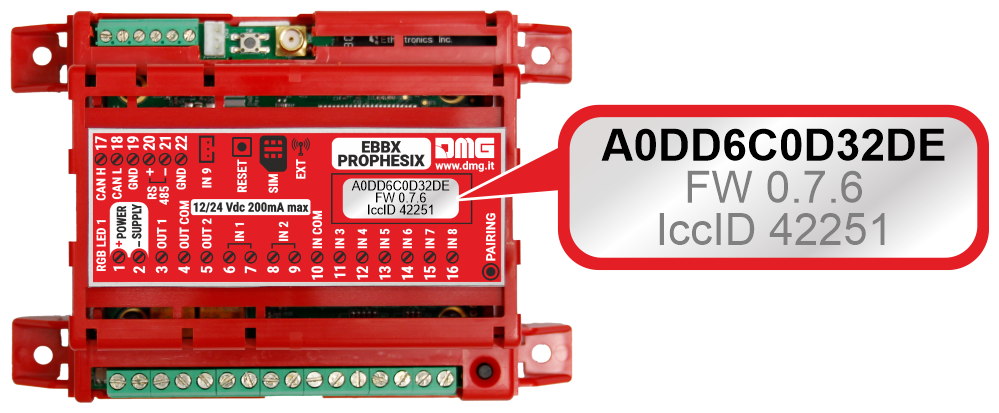

For system operation, the Prophesix device must be associated with the relevant FUSION account.

The device is identified by its unique MAC address, shown on the label on the device, as shown in the image.

Mounting

Electronic control unit

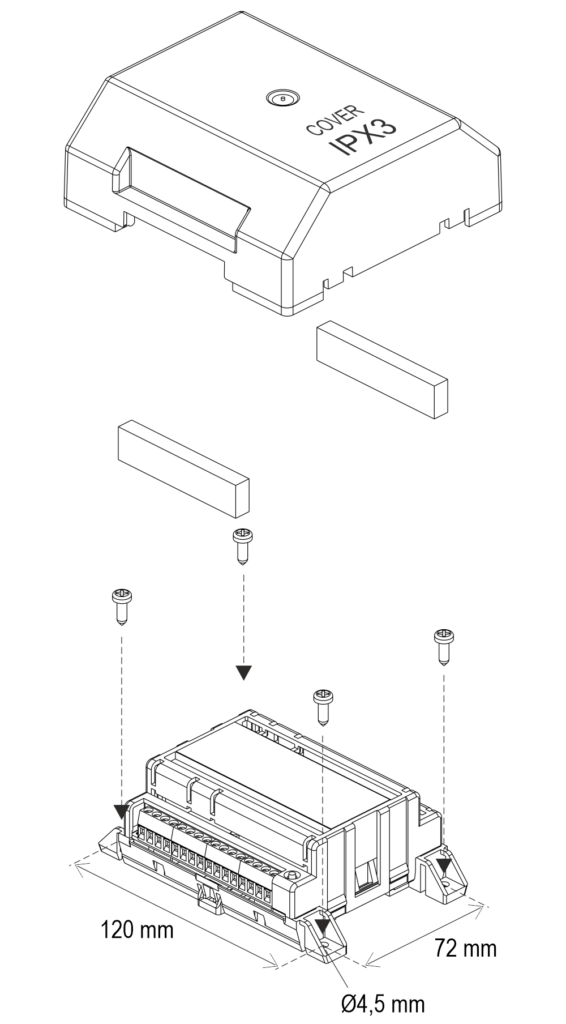

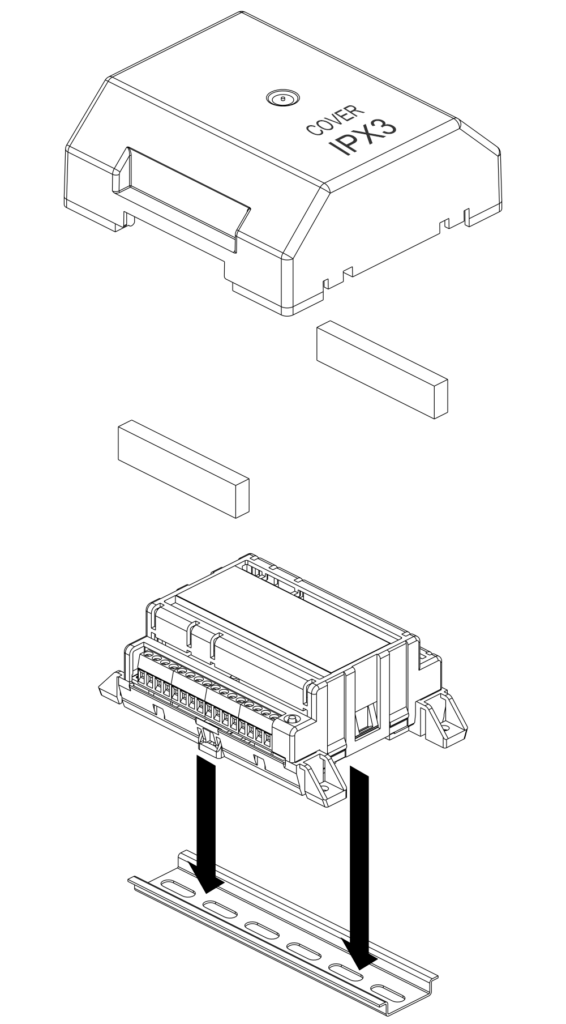

Fixing with screws

DIN rail fixing

Door sensor

The door sensor must be installed on the car doors, secured with double-sided tape (supplied with the device), and positioned as shown in the image.

Installation

First power-on

Power the device and wait until the status LED turns green.

Prophesix then starts transmitting car movement data and environmental parameters to the FUSION cloud platform.

Note:

Prophesix includes an internal energy reserve that keeps the device operational for approximately 5 minutes in the event of a power loss. Full backup capacity is reached about 2 hours after power-up.

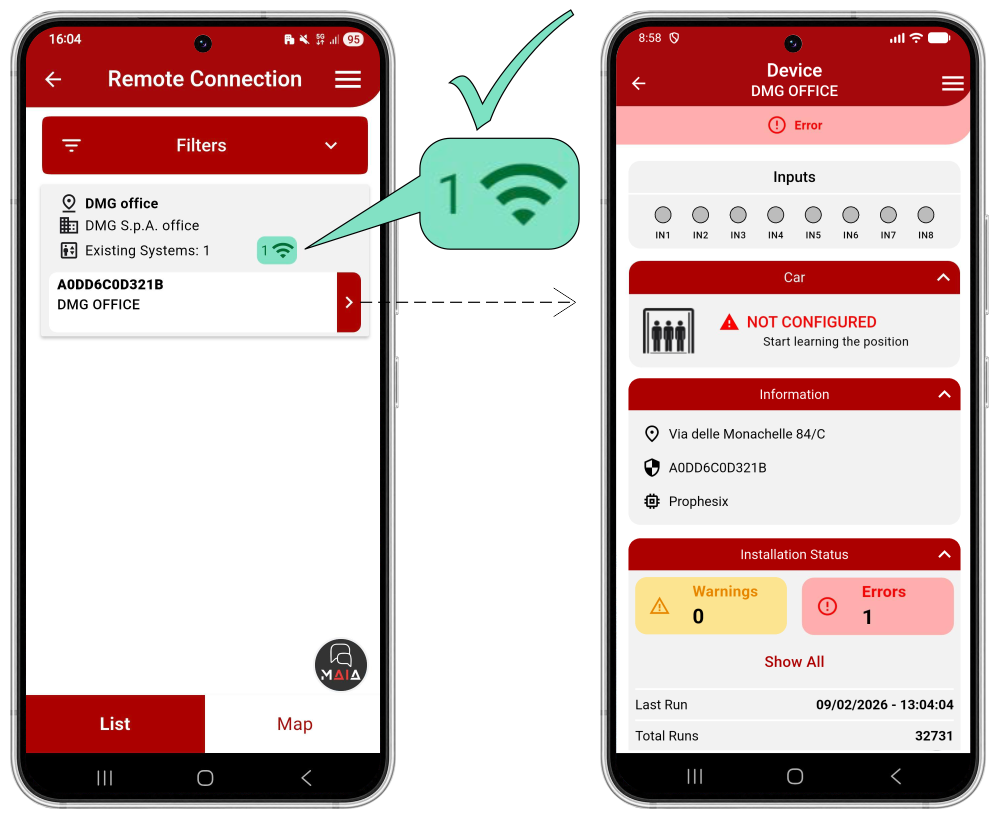

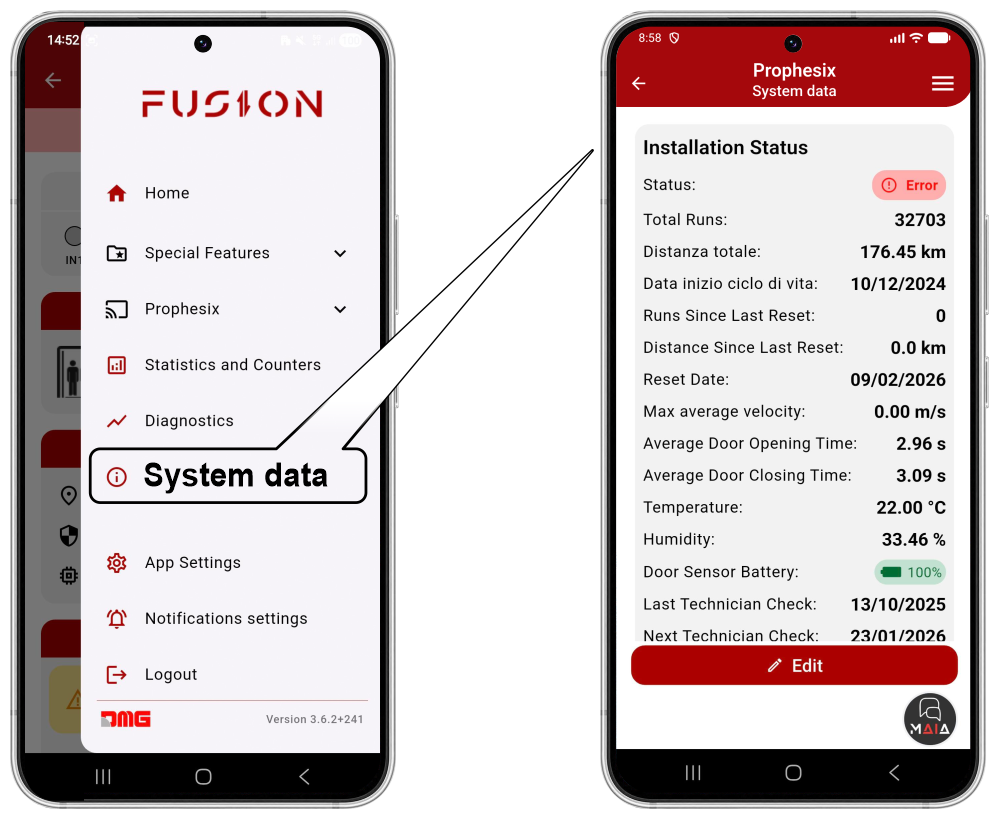

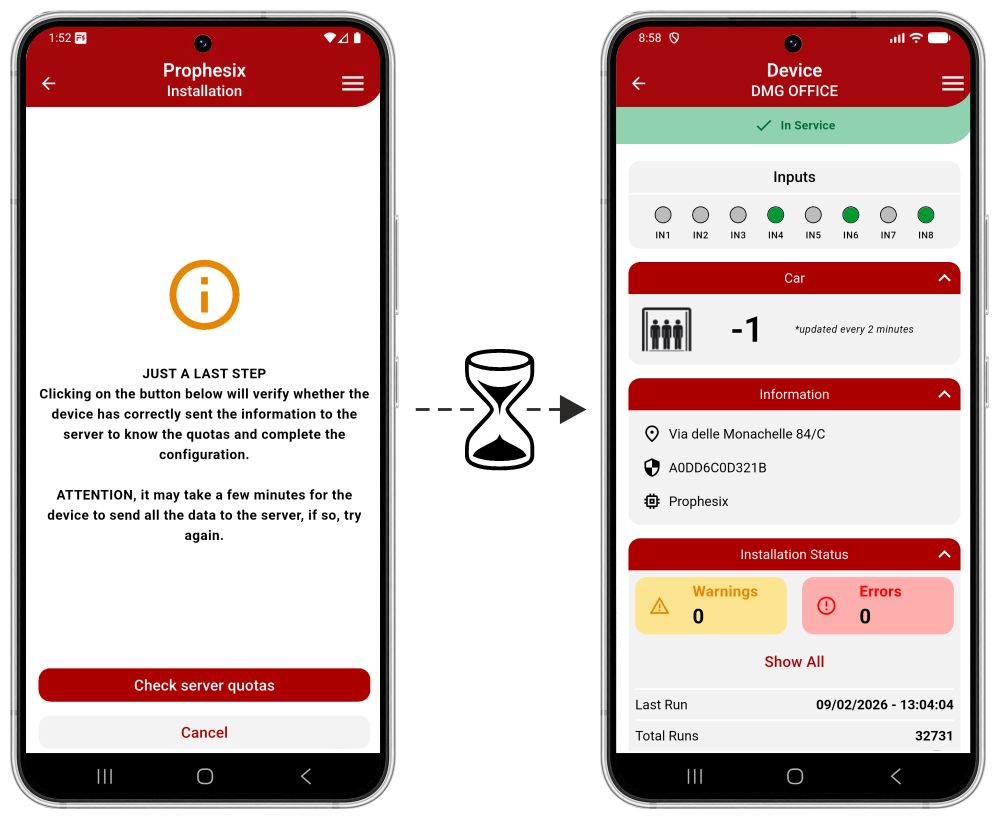

- Open the FUSION app and select PROPHESIX.

- Log in via REMOTE connection.

- Check that the device appears in your device list and that it is connected (green icon).

- Select the device to be managed from the drop-down menu on the right.

The main informations about the elevator status are displayed on the main page of the FUSION app.

The System Data menu allows the user to enter and modify the main system parameters of the installation where the Prophesix device is installed.

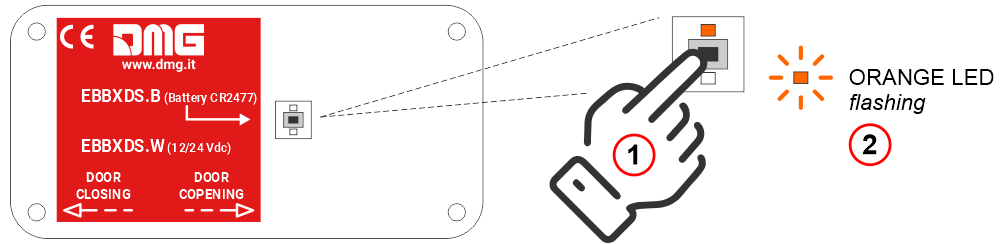

Door sensor pairing (optional)

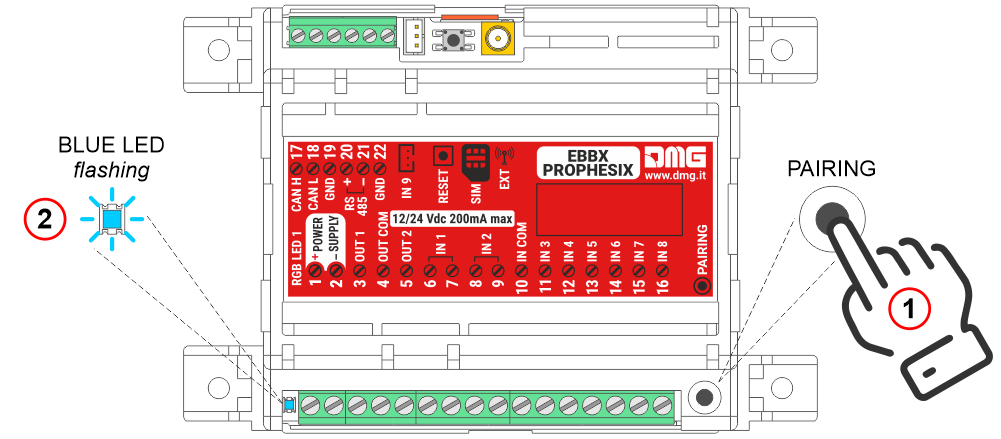

Press the pairing button on the control unit and wait for the blue LED to start flashing.

Remove the cover and install the supplied battery; the LEDs will flash alternately for a few seconds.

Press the pairing button on the door sensor, using a screwdriver, and wait for the orange LED to start flashing.

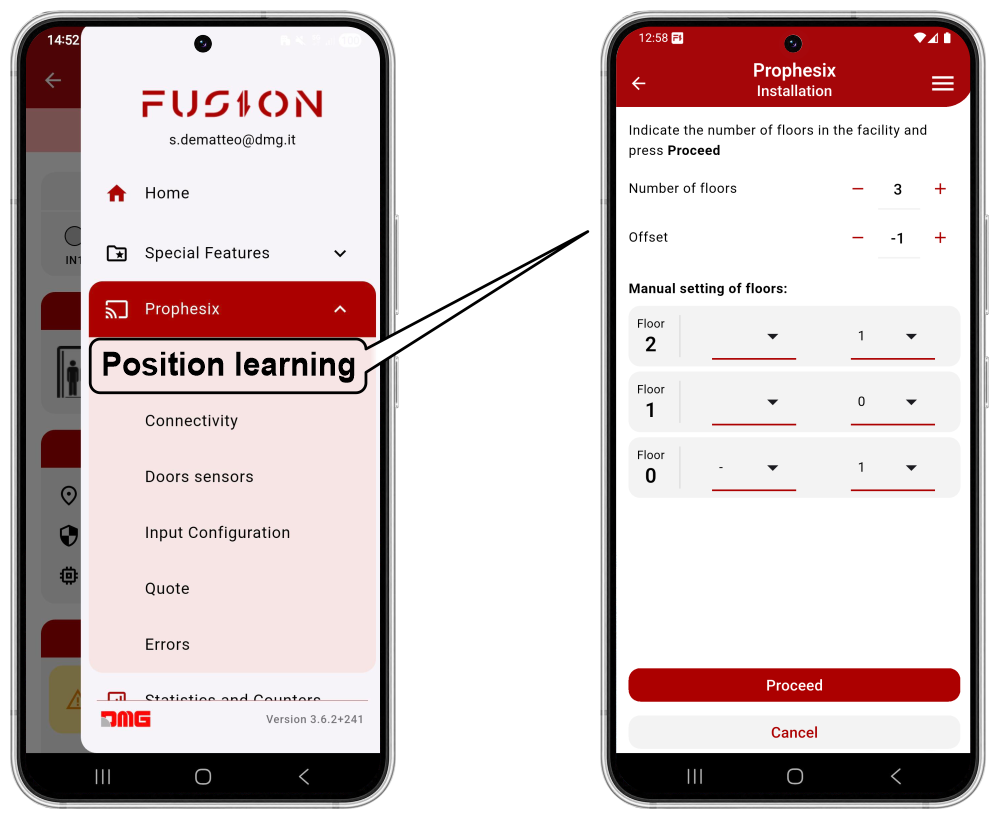

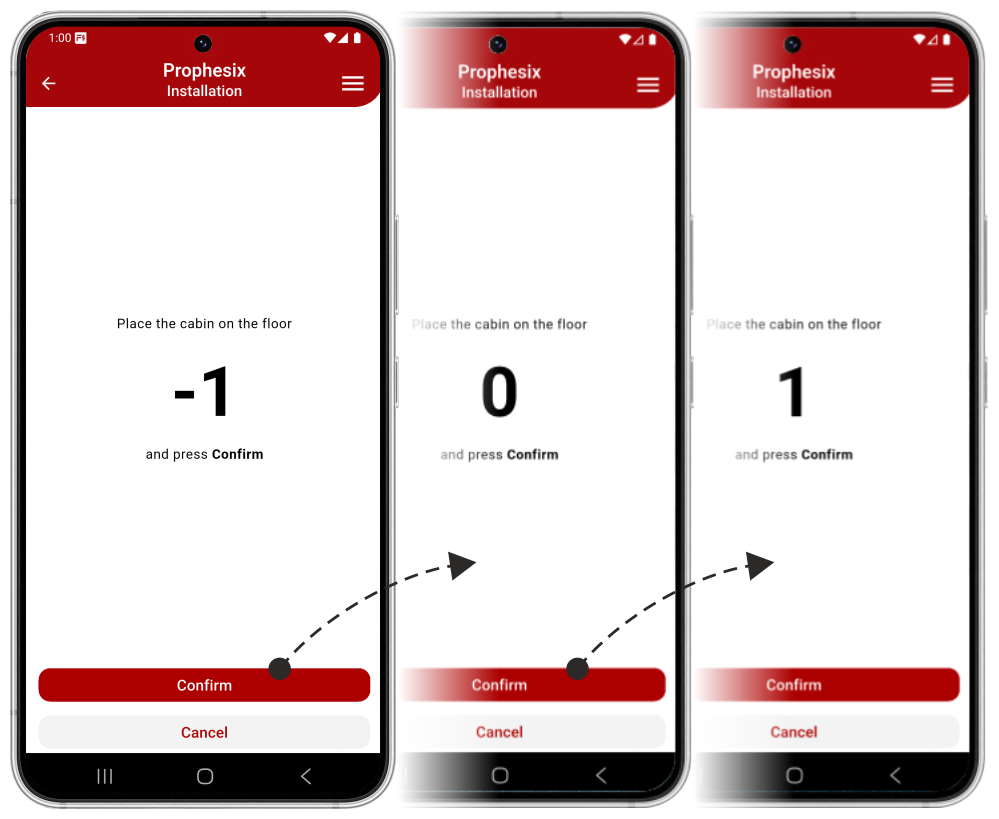

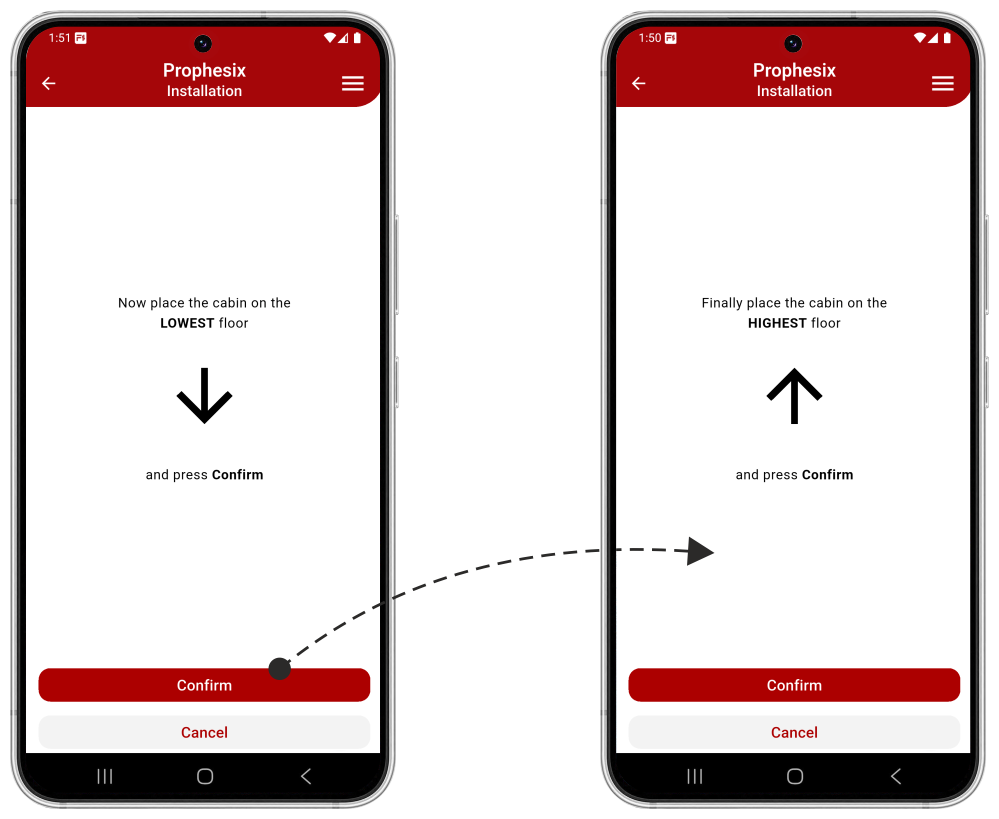

Cabin position learning procedure

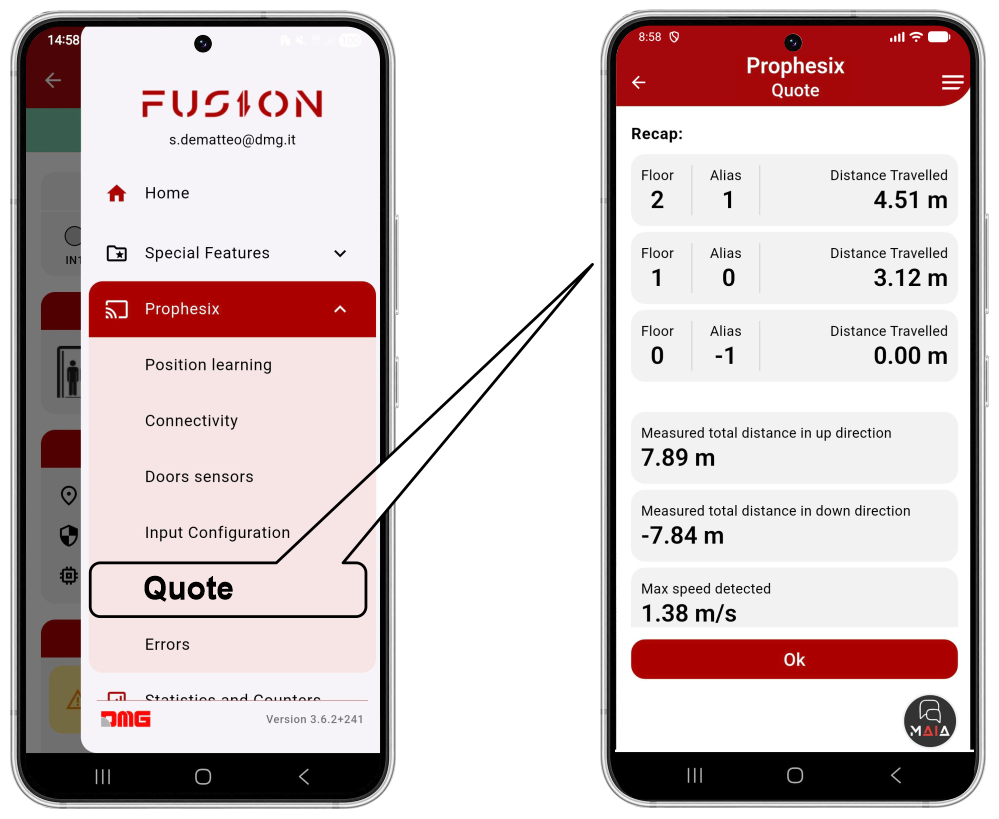

To put the system into operation, follow the guided procedure in the app, which learns the floor heights (inter-floor distances) by performing a series of cabin calls.

From the FUSION app:

- Select the Prophesix device;

- Open the top-right menu and select “Prophesix”, then “Position learning”;

- Move the cabin to the lowest floor.

- Call all floors from bottom to top.

- Perform a full run from the highest floor to the lowest floor.

- Perform a full run from the lowest floor to the highest floor.

At the end of the procedure, without moving the elevator, wait for the data to be transferred from the Prophesix device to the Fusion cloud, which will take approximately 2 minutes.

If the procedure is not successful, it must be repeated.

The acquired data may be verified in the “Prophesix – Quote” menu.

Datasheet

| LLEC7 electronic control unit | |

|---|---|

| Voltage | 12/24V DC |

| Max absorption | 200 mA |

| Relays output 1/2/3 | 1A, 30V DC (Resistive load) |

| Load locking input | Dry contact |

| Operating temperature | -10°c ~ +50°c |

| Car bottom sensor | |

|---|---|

| Range | 800 Kg |

| Input impedance | 1030 ± 10 Ω |

| Output impedance | 1000 ± 2 Ω |

| Insulation Impedance | ≥ 5000M Ω |

| Safe Overload | 150% F.S |

| Ultimate Overload | 200% F.S |

| Temperature Effect | ± 0,02% F.S/10°C |

| Operation Temperature | -30°c ~ +70°c |

| Protection Class | IP67 / IP68 |

| Cable lenght | 6 mt |

| Single rope sensor | |

|---|---|

| Nominal load | 750 Kg (ropes 6~8mm) / 1000 Kg (ropes 9~11mm) / 1000 Kg (ropes 12~15mm) |

| Rated output | 0,5 ~ 2,0 ± 0,1 mV/V |

| Input impedance | 350 ± 20 Ω |

| Output impedance | 350 ± 3 Ω |

| Insulation Impedance | ≥ 5000M Ω /100VDC |

| Recommended excitation | 3,3 V |

| Max excitation | 15 V |

| Safe Overload | 150% F.S |

| Ultimate Overload | 200% F.S |

| Temperature Effect | ± 0,5% F.S/10°C |

| Operation Temperature | -20°c ~ +80°c |

| Protection Class | IP66 |

| Cable lenght | 2 mt |

Troubleshooting

| Problem | Solution |

|---|---|

| The device reports an error at the end of the calibration procedure. | Check the correct connection of the sensors. |

| The device reports an error at the end of the compensation procedure. | Check the correct connection of the magnetic sensors. |

| The weight detected in the car does not seem correct. | Check all the sensors, viewing the weight and output voltage. (see the “Raw Data” menu). |

Usage tips

- On new installations it is advisable to repeat the calibration procedure after some time, since the decrease in friction of the lift could distort the correct functioning of the LLEC7 device.

- It is advisable to never change the length of the sensor cables, as this could influence their factory preset sensitivity.

- Before carrying out the calibration procedure, check that the car is free from any friction with the guides.

- If dummy car bottom sensors are used, the accuracy of the weighing is not guaranteed.

Download

| Reference | Version | Link |

|---|---|---|

| 1.2 | Download PDF (English) | |

| Connection with the Pitagora 4.0 controller | 1.3 | Download PDF (English) |

| Updated commercial codes | 1.4 | Download PDF (English) |

| Disassembly instructions | 1.5 | Download PDF (English) |

| connection of magnetic sensors for travelling cable compensation | 1.6 | |

| Version with single rope sensor | 1.7 | Download PDF (English) |

| Car frame sensor position | 1.8 (current version) | Download PDF (English) |